Matloff, L. Y. et al. How flight feathers stick together to form a continuous morphing wing. Science 367, 293â297 (2020).

Shape shifters. Royal Aeronautical Society www.aerosociety.com/news/shape-shifters/ (2021).

Tawfick, S. & Tang, Y. Stronger artificial muscles, with a twist. Science 365, 125â126 (2019).

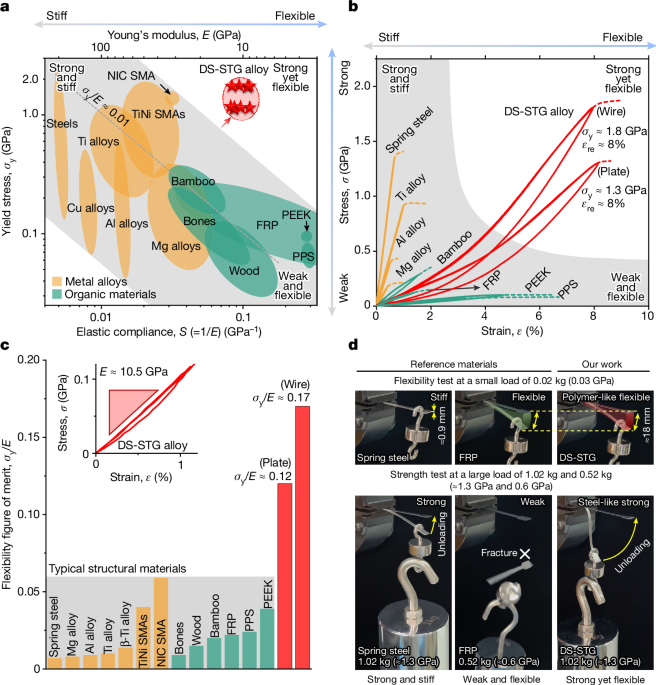

Ashby, M. Materials Selection in Mechanical Design (Elsevier, 2011).

Hao, S. et al. A transforming metal nanocomposite with large elastic strain, low modulus, and high strength. Science 339, 1191â1194 (2013).

Zhu, J., Wang, D., Gao, Y., Zhang, T.-Y. & Wang, Y. Linear-superelastic metals by controlled strain release via nanoscale concentration-gradient engineering. Mater. Today 33, 17â23 (2020).

Liu, C. et al. A lightweight strain glass alloy showing nearly temperature-independent low modulus and high strength. Nat. Mater. 21, 1003â1007 (2022).

Xu, S. et al. Non-Hookean large elastic deformation in bulk crystalline metals. Nat. Commun. 13, 5307 (2022).

Odaira, T. et al. Flexible and tough superelastic CoâCr alloys for biomedical applications. Adv. Mater. 34, 2202305 (2022).

Peng, J. & Snyder, G. J. A figure of merit for flexibility. Science 366, 690â691 (2019).

Zhou, M. Exceptional properties by design. Science 339, 1161â1162 (2013).

Xu, Z. et al. Simultaneously increasing the strength and decreasing the modulus in TiNi alloys via plastic deformation. Scr. Mater. 209, 114374 (2022).

Wu, C.-T. et al. Machine learning recommends affordable new Ti alloy with bone-like modulus. Mater. Today 34, 41â50 (2020).

Zhao, S. et al. Quasiâlinear superelasticity with ultralow modulus in tensile cyclic deformed TiNi strain glass. Adv. Eng. Mater. 24, 2200239 (2022).

Wu, G., Chan, K.-C., Zhu, L., Sun, L. & Lu, J. Dual-phase nanostructuring as a route to high-strength magnesium alloys. Nature 545, 80â83 (2017).

Liang, Q. et al. Strain states and unique properties in cold-rolled TiNi shape memory alloys. Acta Mater. 231, 117890 (2022).

Hua, P., Xia, M., Onuki, Y. & Sun, Q. Nanocomposite NiTi shape memory alloy with high strength and fatigue resistance. Nat. Nanotechnol. 16, 409â413 (2021).

Sun, W. et al. Precipitation strengthening of aluminum alloys by room-temperature cyclic plasticity. Science 363, 972â975 (2019).

Zhang, D. et al. Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature 576, 91â95 (2019).

He, B. B. et al. High dislocation densityâinduced large ductility in deformed and partitioned steels. Science 357, 1029â1032 (2017).

Song, J. et al. Processing bulk natural wood into a high-performance structural material. Nature 554, 224â228 (2018).

Zakikhani, P., Zahari, R., Sultan, M. T. H. & Majid, D. L. Extraction and preparation of bamboo fibre-reinforced composites. Mater. Des. 63, 820â828 (2014).

Abdul Khalil, H. P. S. et al. Bamboo fibre reinforced biocomposites: a review. Mater. Des. 42, 353â368 (2012).

Moniruzzaman, M., Chattopadhyay, J., Billups, W. E. & Winey, K. I. Tuning the mechanical properties of SWNT/nylon 6,10 composites with flexible spacers at the interface. Nano Lett. 7, 1178â1185 (2007).

Li, X. et al. Preparation of polyurethane/polyvinyl alcohol hydrogel and its performance enhancement via compositing with silver particles. RSC Adv. 7, 46480â46485 (2017).

Otsuka, K. & Ren, X. Physical metallurgy of TiâNi-based shape memory alloys. Prog. Mater Sci. 50, 511â678 (2005).

Tanaka, Y. et al. Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science 327, 1488â1490 (2010).

Song, Y., Chen, X., Dabade, V., Shield, T. W. & James, R. D. Enhanced reversibility and unusual microstructure of a phase-transforming material. Nature 502, 85â88 (2013).

Cui, J. et al. Combinatorial search of thermoelastic shape-memory alloys with extremely small hysteresis width. Nat. Mater. 5, 286â290 (2006).

Hou, H. et al. Fatigue-resistant high-performance elastocaloric materials made by additive manufacturing. Science 366, 1116â1121 (2019).

Barrett, R. M. & Barrett, C. M. Biomimetic FAA-certifiable, artificial muscle structures for commercial aircraft wings. Smart Mater. Struct. 23, 074011 (2014).

Gandhi, F. & Anusonti-Inthra, P. Skin design studies for variable camber morphing airfoils. Smart Mater. Struct. 17, 015025 (2008).

Sarkar, S., Ren, X. & Otsuka, K. Evidence for strain glass in the ferroelastic-martensitic system Ti50-xNi50+x. Phys. Rev. Lett. 95, 205702 (2005).

Wang, D., Wang, Y., Zhang, Z. & Ren, X. Modeling abnormal strain states in ferroelastic systems: the role of point defects. Phys. Rev. Lett. 105, 205702 (2010).

Ji, Y. et al. in Encyclopedia of Condensed Matter Physics 2nd edn (ed. Chakraborty, T.) 388â403 (Academic Press, 2024).

Chen, Y. et al. Revealing the mode and strain of reversible twinning in B19â² martensite by in situ synchrotron X-ray diffraction. Acta Mater. 236, 118131 (2022).

Moberly, W. J., Proft, J. L., Duerig, T. W. & Sinclair, R. Deformation, twinning and thermo-mechanical strengthening of Ti50Ni47Fe3. Acta Metall. Mater. 38, 2601â2612 (1990).

Å ittner, P. et al. On the coupling between martensitic transformation and plasticity in NiTi: experiments and continuum based modelling. Prog. Mater Sci. 98, 249â298 (2018).

Molnárová, O., Tyc, O., Heller, L., Seiner, H. & Šittner, P. Evolution of martensitic microstructures in nanocrystalline NiTi wires deformed in tension. Acta Mater. 218, 117166 (2021).

Seiner, H., Sedlák, P., Frost, M. & Šittner, P. Kwinking as the plastic forming mechanism of B19ⲠNiTi martensite. Int. J. Plast. 168, 103697 (2023).

Molnárová, O., Klinger, M., DuchoÅ, J., Seiner, H. & Å ittner, P. Plastic deformation of B19â monoclinic martensite in NiTi shape memory alloys: HRTEM analysis of interfaces in martensite variant microstructures. Acta Mater. 258, 119242 (2023).

Chen, Y. et al. Recoverability of large strains and deformation twinning in martensite during tensile deformation of NiTi shape memory alloy polycrystals. Acta Mater. 180, 243â259 (2019).

Wang, Y., Ren, X. & Otsuka, K. Shape memory effect and superelasticity in a strain glass alloy. Phys. Rev. Lett. 97, 225703 (2006).

Yang, Y. et al. Morphotropic relaxor boundary in a relaxor system showing enhancement of electrostrain and dielectric permittivity. Phys. Rev. Lett. 123, 137601 (2019).

Morawiec, H., Stróż, D., Goryczka, T. & Chrobak, D. Two-stage martensitic transformation in a deformed and annealed NiTi alloy. Scr. Mater. 35, 485â490 (1996).

Zhang, J. et al. Spontaneous strain glass to martensite transition in a Ti50Ni44.5Fe5.5 strain glass. Phys. Rev. B 84, 214201 (2011).

Hertzberg, R. W., Vinci, R. P. & Hertzberg, J. L. Deformation and Fracture Mechanics of Engineering Materials. Fatigue Design (John Wiley & Sons, Inc., 2013).

Liu, Y., Houver, I., Xiang, H., Bataillard, L. & Miyazaki, S. Strain dependence of pseudoelastic hysteresis of NiTi. Metall. Mater. Trans. A 30, 1275â1282 (1999).

Chen, H. et al. Improvement of the stability of superelasticity and elastocaloric effect of a Ni-rich Ti-Ni alloy by precipitation and grain refinement. Scr. Mater. 162, 230â234 (2019).

Zhang, J., Chen, T., Li, W., Bednarcik, J. & Dippel, A.-C. High temperature superelasticity realized in equiatomic Ti-Ni conventional shape memory alloy by severe cold rolling. Mater. Des. 193, 108875 (2020).