Vishakha, S. K., Kishor, D. B. & Sudha, S. R. Natural polymers–a comprehensive review. Int. J. Res. Pharm. Biomed. Sci. 3, 1597–1613 (2012).

Muhammadi, Shabina, Afzal, M. & Hameed, S. Bacterial polyhydroxyalkanoates-eco-friendly next generation plastic: production, biocompatibility, biodegradation, physical properties and applications. Green Chem. Lett. Rev. 8, 56–77 (2015).

Tutoni, G. G. et al. Microfluidic assembly of degradable, stereocomplexed hydrogel Microparticles. J. Am. Chem. Soc. 146, 14705–14714 (2024).

Popowski, Y., Lu, Y., Coates, G. W. & Tolman, W. B. Stereocomplexation of stereoregular aliphatic polyesters: change from amorphous to semicrystalline polymers with single stereocenter inversion. J. Am. Chem. Soc. 144, 8362–8370 (2022).

Auriemma, F. et al. Stereocomplexed poly(limonene carbonate): a unique example of the cocrystallization of amorphous enantiomeric polymers. Angew. Chem. Int. Ed. 54, 1215–1218 (2015).

Hori, Y., Suzuki, M., Yamaguchi, A. & Nishishita, T. Ring-opening polymerization of optically active β-butyrolactone using distannoxane catalysts: synthesis of high-molecular-weight poly(3-hydroxybutyrate). Macromolecules 26, 5533–5534 (1993).

Zheng, Y. & Pan, P. Crystallization of biodegradable and biobased polyesters: polymorphism, cocrystallization, and structure-property relationship. Prog. Polym. Sci. 109, 101291 (2020).

Worch, J. C. et al. Stereochemical enhancement of polymer properties. Nat. Rev. Chem. 3, 514–535 (2019).

García, F., Gómez, R. & Sánchez, L. Chiral supramolecular polymers. Chem. Soc. Rev. 52, 7524–7548 (2023).

Shen, J. & Okamoto, Y. Efficient separation of enantiomers using stereoregular chiral polymers. Chem. Rev. 116, 1094–1138 (2016).

Kakuchi, T. & Sakai, R. in Encyclopedia Polymer Science Technology Vol. 3, 1–32 (Wiley, 2014).

Yashima, E., Maeda, K., Iida, H., Furusho, Y. & Nagai, K. Helical polymers: synthesis, structures, and functions. Chem. Rev. 109, 6102–6211 (2009).

Westlie, A. H., Quinn, E. C., Parker, C. R. & Chen, E. Y.-X. Synthetic biodegradable polyhydroxyalkanoates (PHAs): recent advances and future challenges. Prog. Polym. Sci. 134, 101608 (2022).

Anjum, A. et al. Microbial production of polyhydroxyalkanoates (PHAs) and its copolymers: a review of recent advancements. Int. J. Biol. Macromol. 89, 161–174 (2016).

Sudesh, K., Abe, H. & Doi, Y. Synthesis, structure and properties of polyhydroxyalkanoates: biological polyesters. Prog. Polym. Sci. 25, 1503–1555 (2000).

Shoda, S. I., Uyama, H., Kadokawa, J. I., Kimura, S. & Kobayashi, S. Enzymes as green catalysts for precision macromolecular synthesis. Chem. Rev. 116, 2307–2413 (2016).

Kobayashi, S. & Makino, A. Enzymatic polymer synthesis: an opportunity for green polymer chemistry. Chem. Rev. 109, 5288–5353 (2009).

Xu, G. et al. Asymmetric kinetic resolution polymerization. Coord. Chem. Rev. 414, 213296 (2020).

Young, M. S., LaPointe, A. M., MacMillan, S. N. & Coates, G. W. Highly enantioselective polymerization of β-butyrolactone by a bimetallic magnesium catalyst: an interdependent relationship between favored and unfavored enantiomers. J. Am. Chem. Soc. 146, 18032–18040 (2024).

Huang, H.-Y. et al. Spiro-salen catalysts enable the chemical synthesis of stereoregular polyhydroxyalkanoates. Nat. Catal. 6, 720–728 (2023).

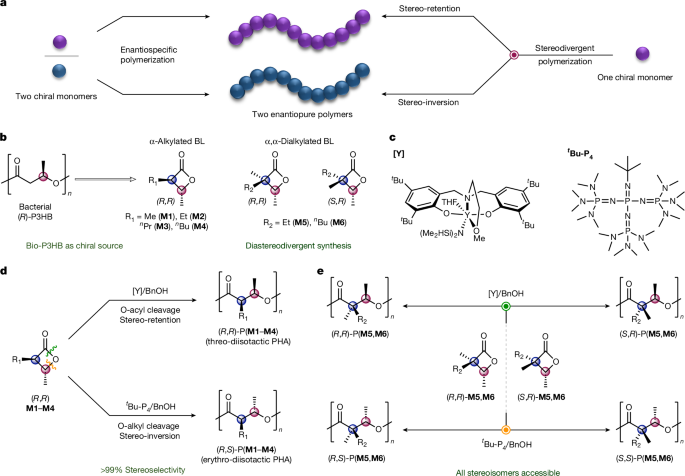

Beletskaya, I. P., Najera, C. & Yus, M. Stereodivergent catalysis. Chem. Rev. 118, 5080–5200 (2018).

Krautwald, S. & Carreira, E. M. Stereodivergence in asymmetric catalysis. J. Am. Chem. Soc. 139, 5627–5639 (2017).

Quinn, E. C. et al. Installing controlled stereo-defects yields semicrystalline and biodegradable poly(3-hydroxybutyrate) with high toughness and optical clarity. J. Am. Chem. Soc. 145, 5795–5802 (2023).

Bruckmoser, J., Pongratz, S., Stieglitz, L. & Rieger, B. Highly isoselective ring-opening polymerization of rac-β-butyrolactone: access to synthetic poly(3-hydroxybutyrate) with polyolefin-like material properties. J. Am. Chem. Soc. 145, 11494–11498 (2023).

Tang, X. et al. Biodegradable polyhydroxyalkanoates by stereoselective copolymerization of racemic diolides: stereocontrol and polyolefin-like properties. Angew. Chem. Int. Ed. 59, 7881–7890 (2020).

Grassie, N., Murray, E. J. & Holmes, P. A. The thermal degradation of poly(-(D)-β-hydroxybutyric acid): part 3—the reaction mechanism. Polym. Degrad. Stab. 6, 127–134 (1984).

Morikawa, H. & Marchessault, R. H. Pyrolysis of bacterial polyalkanoates. Can. J. Chem. 59, 2306–2313 (1981).

Zhou, L. et al. Chemically circular, mechanically tough, and melt-processable polyhydroxyalkanoates. Science 380, 64–69 (2023).

Zhou, Z., LaPointe, A. M., Shaffer, T. D. & Coates, G. W. Nature-inspired methylated polyhydroxybutyrates from C1 and C4 feedstocks. Nat. Chem. 15, 856–861 (2023).

Zhou, Z., LaPointe, A. M. & Coates, G. W. Atactic, isotactic, and syndiotactic methylated polyhydroxybutyrates: an unexpected series of isomorphic polymers. J. Am. Chem. Soc. 145, 25983–25988 (2023).

Yang, J.-C., Yang, J., Li, W.-B., Lu, X.-B. & Liu, Y. Carbonylative polymerization of epoxides mediated by tri-metallic complexes: a dual catalysis strategy for synthesis of biodegradable polyhydroxyalkanoates. Angew. Chem. Int. Ed. 61, e202116208 (2022).

Furutate, S. et al. Superior thermal stability and fast crystallization behavior of a novel, biodegradable α-methylated bacterial polyester. npg Asia Mater. 13, 31 (2021).

Tanahashi, N. & Doi, Y. Thermal properties and stereoregularity of poly(3-hydroxybutyrate) prepared from optically active β-butyrolactone with a zinc-based catalyst. Macromolecules 24, 5732–5733 (1991).

Zhang, Y., Gross, R. A. & Lenz, R. W. Stereochemistry of the ring-opening polymerization of (S)-β-butyrolactone. Macromolecules 23, 3206–3212 (1990).

Rieth, L. R., Moore, D. R., Lobkovsky, E. B. & Coates, G. W. Single-site β-diiminate zinc catalysts for the ring-opening polymerization of β-butyrolactone and β-valerolactone to poly(3-hydroxyalkanoates). J. Am. Chem. Soc. 124, 15239–15248 (2002).

Shakaroun, R. M., Jéhan, P., Alaaeddine, A., Carpentier, J. F. & Guillaume, S. M. Organocatalyzed ring-opening polymerization (ROP) of functional β-lactones: new insights into the ROP mechanism and poly(hydroxyalkanoate)s (PHAs) macromolecular structure. Polym. Chem. 11, 2640–2652 (2020).

Jedlinski, Z. et al. Stereochemical control in the anionic polymerization of β-butyrolactone initiated with alkali-metal alkoxides. Macromolecules 29, 3773–3777 (1996).

Kurcok, P., Kowalczuk, M., Hennek, K. & Jedlinski, Z. Anionic polymerization of β-lactones initiated with alkali-metal alkoxides: reinvestigation of the polymerization mechanism. Macromolecules 25, 2017–2020 (1992).

Li, Z., Zhao, D., Shen, Y. & Li, Z. Ring-opening polymerization of enantiopure bicyclic ether-ester monomers toward closed-loop recyclable and crystalline stereoregular polyesters via chemical upcycling of bioplastic. Angew. Chem. Int. Ed. 62, e202302101 (2023).

Amgoune, A., Thomas, C. M., Ilinca, S., Roisnel, T. & Carpentier, J. Highly active, productive, and syndiospecific yttrium initiators for the polymerization of racemic β‐butyrolactone. Angew. Chem. Int. Ed. 45, 2782–2784 (2006).

De Winter, J., Coulembier, O., Gerbaux, P. & Dubois, P. High molecular weight poly(α,α′,β-trisubstituted β-lactones) as generated by metal-free phosphazene catalysts. Macromolecules 43, 10291–10296 (2010).

Fráter, G., Müller, U. & Günther, W. The stereoselective α-alkylation of chiral β-hydroxy esters and some applications thereof. Tetrahedron 40, 1269–1277 (1984).

Tutoni, G. & Becker, M. L. Underexplored stereocomplex polymeric scaffolds with improved thermal and mechanical properties. Macromolecules 53, 10303–10314 (2020).

Im, S. H. et al. Stereocomplex polylactide for drug delivery and biomedical applications: a review. Molecules 26, 2846 (2021).

Tang, X. & Chen, E. Y.-X. Chemical synthesis of perfectly isotactic and high melting bacterial poly(3-hydroxybutyrate) from bio-sourced racemic cyclic diolide. Nat. Commun. 9, 2345 (2018).

Amgoune, A., Thomas, C. M., Roisnel, T. & Carpentier, J.-F. Ring‐opening polymerization of lactide with group 3 metal complexes supported by dianionic alkoxy‐amino‐bisphenolate ligands: combining high activity, productivity, and selectivity. Chem. Eur. J. 12, 169–179 (2006).