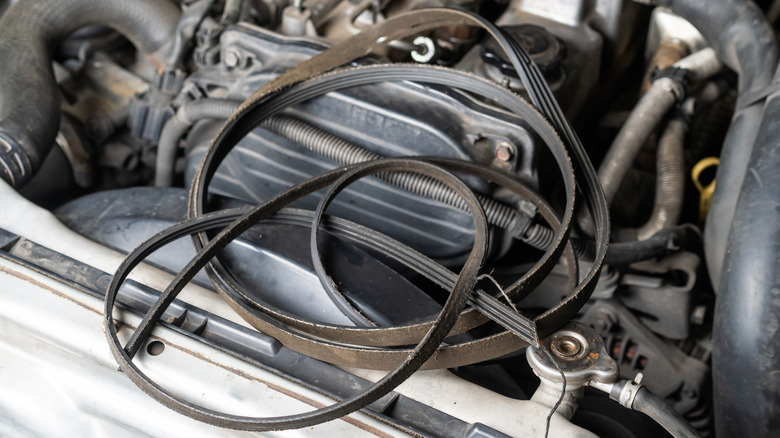

By now, we all should know what could happen if our timing belt snaps, but what about the timing belt’s partner in crime, the serpentine belt? Serpentine belts are the overachievers of the engine bay. One long rubber loop can control everything from your alternator to the air conditioning compressor to the power steering pump. It’s basically the multitasking intern of your engine — doing a dozen jobs, never complaining, until it snaps and suddenly you’re the one sweating.

Despite doing so much, most of us forget the serpentine belt even exists — let alone that its tension matters. But it does. A lot. Too tight and it’ll grind bearings to dust. Too loose and you’re listening to the high-pitched scream of rubber slipping. That’s why even a faint squeal or mysterious under-hood smell deserves your attention before your engine accessories go on strike. However, how do you diagnose the problem, and even more, how do you prevent any issues from happening?

Manual vs. spring vs. hydraulic tensioners

When it comes to serpentine belt tension, how your engine maintains it makes all the difference. Older engines often rely on a manual tensioner — a threaded bolt adjusted pulley that requires manual adjustment and frequent checks. If your project car keeps eating belts, this might be why. The tricky part? There is no formal metric, spec, or owner’s manual reference for how tight is tight enough.

Spring-loaded automatic tensioners are the most common today, introduced in the mid-1980s. They use a coil spring to apply constant tension and usually self-correct for minor belt stretch over time. The downside? Just like a mattress, that spring fatigues over time. Once it loses force, your belt may start to slip or fray without any obvious warning.

Some high-end or higher horsepower cars use hydraulic tensioners – think similarly to the shocks in a suspension. These offer better dampening performance compared to the other designs. They’re great — until they leak and then stop dampening like they’re supposed to.Each design has its strengths and weaknesses, but all three will ruin your day if you forget they exist. You’re not just checking the belt — you’re checking the whole system that keeps it honest.

Diagnosing and preventing serpentine belt tension issues

Modern cars use automatic belt tensioners, whether spring or hydraulic styles, but “automatic” doesn’t mean “foolproof.” You’ll know you have a problem if you hear squealing during startup, notice accessory power drops (like a dying battery, intermittent A/C, or lights flickering), or spot glazing, cracking, or fraying on the belt itself.

Checking proper tension isn’t complicated. Some swear by the twist test (belt should rotate about 90 degrees by hand) while others use belt tension gauges. A simple visual inspection of the serpentine belt while your engine is running can sometimes show a fluttering belt. This can be an indication of a failing tensioner; just keep your fingers clear of any moving objects. Replacement difficulty varies by models, but if you’ve got a basic tool kit and a diploma from YouTube U, you’re halfway there.

Your car is only as strong as its weakest part, and if that part is your neglected serpentine belt or tensioner, you’re just a few rotations away from a smoking engine bay. Giving that belt a quick once-over takes seconds. Ignoring it could cost you a tow truck, a weekend, and one or two trips to the parts store.