Abas, N. et al. Natural and synthetic refrigerants, global warming: a review. Renew. Sustain. Energy Rev. 90, 557–569 (2018).

Garimella, S. et al. Realistic pathways to decarbonization of building energy systems. Joule 6, 956–971 (2022).

Esper, J. et al. 2023 summer warmth unparalleled over the past 2,000 years. Nature 631, 94–97 (2024).

Cui, J. et al. Demonstration of high efficiency elastocaloric cooling with large ΔT using NiTi wires. Appl. Phys. Lett. 101, 073904 (2012).

Li, L. et al. Cooling innovations: elastocaloric shape memory alloys, manufacturing, simulation, and refrigerator. Prog. Mater. Sci. 153, 101477 (2025).

Cui, J. Early efforts on elastocaloric cooling (2002 to 2014). Shape Mem. Superelasticity 10, 80–88 (2024).

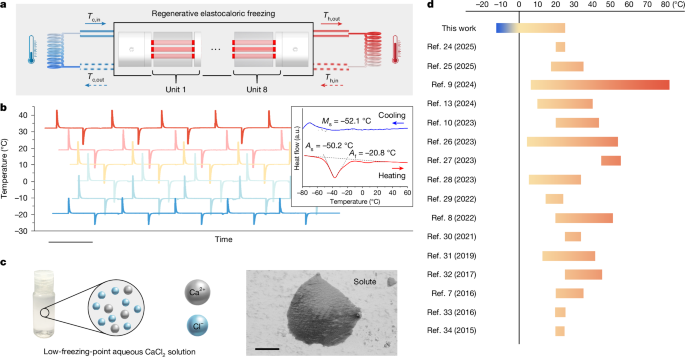

Tusek, J. et al. A regenerative elastocaloric heat pump. Nat. Energy 1, 16134 (2016).

Ahcin, Z. et al. High-performance cooling and heat pumping based on fatigue-resistant elastocaloric effect in compression. Joule 6, 2338–2357 (2022).

Zhou, G. et al. A multi-material cascade elastocaloric cooling device for large temperature lift. Nat. Energy 9, 862–870 (2024).

Qian, S. et al. High-performance multimode elastocaloric cooling system. Science 380, 722–727 (2023).

Li, X. et al. High-frequency bending-actuated elastocaloric cooler with enhanced cooling performance. Cell Rep. Phys. Sci. 6, 102669 (2025).

Dall’Olio, S. et al. Development of a tube-based elastocaloric regenerator loaded in compression: a review. Shape Mem. Superelasticity 10, 99–118 (2024).

Xu, J. et al. SMA film-based elastocaloric cooling devices. Shape Mem. Superelasticity 10, 119–133 (2024).

Manosa, L. & Planes, A. Solid-state cooling by stress: a perspective. Appl. Phys. Lett. 116, 050501 (2020).

Bruederlin, F. et al. SMA foil-based elastocaloric cooling: from material behavior to device engineering. J. Phys. D Appl. Phys. 50, 424003 (2017).

Kawarada, Y. et al. Abnormal grain growth of 68Cu–16Al–16Zn alloys for elastocaloric cooling via cyclical heat treatments. J. Phys. Energy 5, 024012 (2023).

Qian, S. et al. Elastocaloric effect in CuAlZn and CuAlMn shape memory alloys under compression. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 374, 20150309 (2016).

Franco, V. et al. Magnetocaloric effect: from materials research to refrigeration devices. Prog. Mater. Sci. 93, 112–232 (2018).

Hou, H. et al. Materials, physics and systems for multicaloric cooling. Nat. Rev. Mater. 7, 633–652 (2022).

Hilliard, B. et al. Magnetocaloric effect in Gd1-xCexNi (x = 0-0.6): a cost-effective approach to tuning Curie temperature from 70 K to 30 K. J. Alloys Compd. 989, 174186 (2024).

Archipley, C. et al. Methane liquefaction with an active magnetic regenerative refrigerator. Cryogenics 128, 103588 (2022).

Kabirifar, P. et al. From the elastocaloric effect towards an efficient thermodynamic cycle. J. Phys. Energy 4, 044009 (2022).

N’Tsoukpoe, K. et al. A review on the use of calcium chloride in applied thermal engineering. Appl. Therm. Eng. 75, 513–531 (2015).

Wang, K. et al. A 3D-printed full-soft regenerative elastocaloric cooler. Energy Convers. Manag. 336, 119811 (2025).

Liu, Y. et al. Numerical simulation and experimental investigation of a novel elastocaloric air conditioning system. Appl. Therm. Eng. 274, 126643 (2025).

Zhou, G. et al. Giant temperature span and cooling power in elastocaloric regenerator. Joule 7, 2003–2015 (2023).

Hartquist, C. et al. An elastomer with ultrahigh strain-induced crystallization. Sci. Adv. 9, eadj0411 (2023).

Zhang, J. et al. Highly efficient grooved NiTi tube refrigerants for compressive elastocaloric cooling. Appl. Therm. Eng. 228, 120439 (2023).

Chen, Y. et al. A compact elastocaloric refrigerator. The Innovation 3, 100205 (2022).

Greibich, F. et al. Elastocaloric heat pump with specific cooling power of 20.9 W g−1 exploiting snap-through instability and strain-induced crystallization. Nat. Energy 6, 260–267 (2021).

Snodgrass, R. & Erickson, D. A multistage elastocaloric refrigerator and heat pump with 28 K temperature span. Sci. Rep. 9, 18532 (2019).

Engelbrecht, K. et al. A regenerative elastocaloric device: experimental results. J. Phys. D Appl. Phys. 50, 424006 (2017).

Ossmer, H. et al. Energy-efficient miniature-scale heat pumping based on shape memory alloys. Smart Mater. Struct. 25, 085037 (2016).

Schmidt, M. et al. Scientific test setup for investigation of shape memory alloy based elastocaloric cooling processes. Int. J. Refrig 54, 88–97 (2015).

Zhang, K. et al. Interactions among phase transition, heat transfer and austenite plasticity in cyclic compression of NiTi shape memory alloys: effect of loading frequency. J. Mech. Phys. Solids 191, 105782 (2024).

Zimmermann, D. et al. Modeling moist air effects and shape memory alloys in elastocaloric devices. Front. Mater. 12, 1559800 (2025).

Hua, P. et al. Nanocomposite NiTi shape memory alloy with high strength and fatigue resistance. Nat. Nanotechnol. 16, 409–413 (2021).

Lin, H. et al. Grain boundary and dislocation strengthening of nanocrystalline NiTi for stable elastocaloric cooling. Scr. Mater. 226, 115227 (2023).

Xu, B. et al. Enhanced cyclic stability of NiTi shape memory alloy elastocaloric materials with Ni4Ti3 nanoprecipitates: experiment and phase field modeling. J. Mech. Phys. Solids 196, 106011 (2025).

Ren, S. et al. Corrosion testing of metals in contact with calcium chloride hexahydrate used for thermal energy storage. Mater. Corros. 68, 1046–1056 (2017).

ASTM International. G46-94. Standard guide for examination and evaluation of pitting corrosion. iTeh https://doi.org/10.1520/G0046-94R05 (2005).

Wang, J. et al. Machine-assisted quantification of droplet boiling upon multiple solid materials. Nano Energy 125, 109560 (2024).

Zhu, Y. et al. A numerical study of elastocaloric regenerators of tubular structures. Appl. Energy 339, 120990 (2023).

Yao, S. et al. Efficient roller-driven elastocaloric refrigerator. Nat. Commun. 15, 7203 (2024).

Ritchie H. Sector by sector: where do global greenhouse gas emissions come from? Our World in Data https://ourworldindata.org/ghg-emissions-by-sector (2020).

Velders, G. et al. Projections of hydrofluorocarbon (HFC) emissions and the resulting global warming based on recent trends in observed abundances and current policies. Atmos. Chem. Phys. 22, 6087–6101 (2022).

UNEP Ozone Secretariat. Fact Sheet 2. Overview of HFC Market Sectors. UN Environment Programme https://ozone.unep.org/sites/ozone/files/Meeting_Documents/HFCs/FS_2_Overview_of_HFC_Markets_Oct_2015.pdf (2015).

Zhou, G. et al. Achieving kilowatt-scale elastocaloric cooling by a multi-cell architecture. Nature 639, 87–92 (2025).

Cirillo, L. et al. 2D thermo-fluidynamic rotary model of an elastocaloric cooling device: the energy performances. Energy Convers. Manag. X 23, 100635 (2024).

Wang, K. et al. Numerical study of enhanced cooling in active elastocaloric regenerators with porous woven structures. Appl. Energy 395, 126180 (2025).

Xu, J. Exceeding the kilowatt threshold. Nat. Energy 10, 1187–1188 (2025).