Synthetic biology is poised to tackle a range of challenges, from cleaning up pollutants with designer bacteria to the creation of bespoke gene therapies. But the transition from the laboratory to commercial use will require advances in DNA-synthesis technology.

For decades, the only way to make industrial volumes of custom DNA has been phosphoramidite synthesis, an organic-chemistry process that can construct nucleic acids up to 350 nucleotides or so in length. To produce longer fragments, DNA manufacturers build thousands of oligonucleotides, or oligos, in parallel, and then assemble them. This technique can pump out large volumes of DNA at low cost, but it struggles with sequences that are highly repetitive or complex.

The race for enzymatic DNA synthesis heats up

Now, advances in both enzymatic and chemical synthesis are clearing those hurdles.

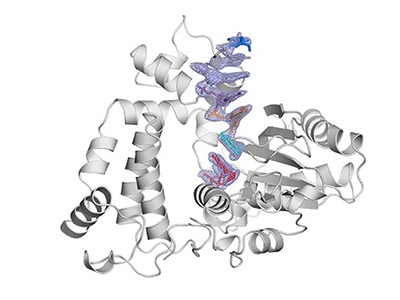

Enzymatic synthesis is inspired by the method that living cells use to replicate DNA. Usually, cells copy DNA from a template rather than creating it from scratch. But that works only if the template exists, which is not the case for the custom DNAs that synthetic biologists need. An enzyme called terminal deoxynucleotidyl transferase (TdT) can join nucleotides together without a template, and several companies have begun commercializing enzymatic methods that exploit it.

DNA Script, based in Paris, couples TdT with chemically modified nucleotides that prevent elongation by more than one monomer at a time. After each base is added, the protective cap is removed and washed away, another base is added and the cycle repeats. Ansa Biotechnologies takes a similar approach, but rather than using a blocking group to restrict elongation, the company, in Emeryville, California, tethers the base to TdT so that the enzyme stays bound to the growing oligo. A second enzyme cleaves the linker after elongation, allowing the cycle to continue.

Thomas Ybert, chief scientific officer at DNA Script in Paris.Credit: ERIC PIERMONT/AFP via Getty

According to Daniel Lin-Arlow, Ansa’s chief scientific officer, the approach can handle sequences with highly complex secondary structures, including repeats, hairpins or high guanine–cytosine content, which are otherwise difficult to produce. In August 2024, the company launched its first commercial product, a 600-base custom service, which can be assembled into constructs of up to 5 kilobases. “We found a lot of interest from people who were working on non-coding sequences, like promoters,” Lin-Arlow says, which cannot be changed to make them easier to manufacture. And the technology continues to advance: early-access customers can now request DNAs as long as 750 bases, and clonal assemblies up to 50 kbp in length.

Enzymatic synthesis is also making benchtop DNA synthesizers more accessible. Phosphoramidite-based DNA synthesizers require specialized training and infrastructure to safely handle toxic organic reagents and waste. By contrast, enzymatic synthesizers require only basic liquid-handling skills. In 2023, DNA Script began selling its SYNTAX system, a device that researchers can use to synthesize 96 oligos in parallel, with up to about 120 nucleotides per oligo, per day. “It’s as easy to use as your office printer,” says Thomas Ybert, the firm’s chief scientific officer.

Chemical improvements

New organic-chemistry methods are also emerging to tackle long-DNA synthesis.