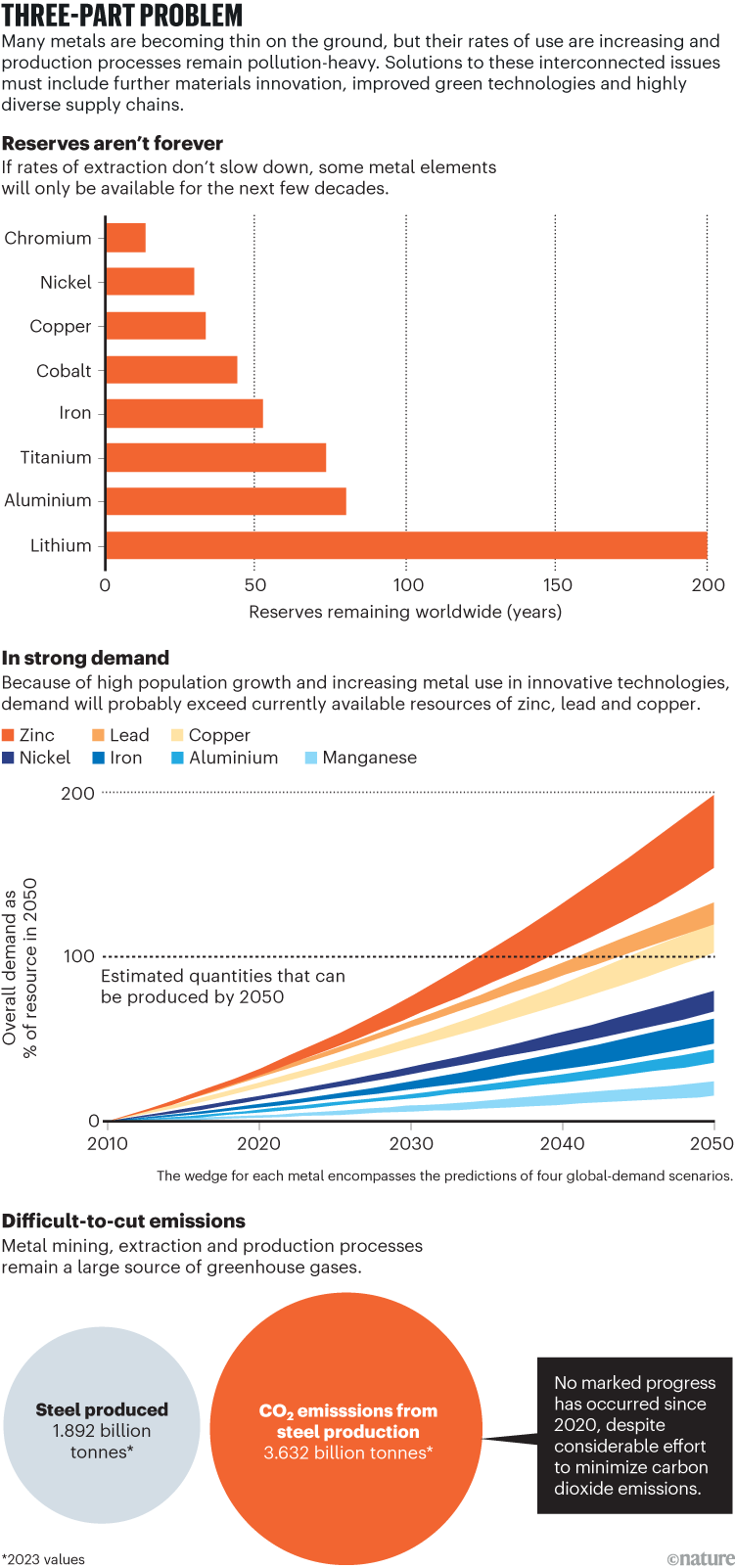

Metals are at the heart of the global economy, from power generation and storage to transport. But their supply chains face three interlinked challenges: dwindling reserves, rising demand and high greenhouse-gas emissions1–3.

At the current rates of extraction and use, the known reserves of some metals, including copper, nickel and chromium, will only last for the next few decades1,2. And these rates do not take into account rising demand as the world’s population grows and new technologies emerge3 (see ‘Three-part problem’).

Furthermore, the mining and extraction of most metals, as well as their melting, refining, alloying, casting and shaping, are a large source of greenhouse gases. Steelmaking alone accounts for about 8% of global carbon dioxide emissions, or 3.6 billion tonnes3 — more than three times what the aviation sector contributes.

There are currently no concrete, commonly accepted long-term solutions or implementation plans. Here, based on our expertise in materials science and engineering, we outline a set of five strategies that, together, can address the challenges. The solutions that societies choose will have wide-reaching consequences for our ways of life, economy and the well-being of our planet and future generations.

Sources: Reserves: ref. 1; In demand: ref. 2; Emissions: World Steel in Figures 2024 and Sustainability Indicators 2024 reports (World Steel Association)

Swap materials

A small tweak in a material’s chemical composition can go a long way in reducing the amount of metals used. Take steel, for example. About one billion tonnes of carbon–manganese steel are used each year globally for buildings and other infrastructure. However, using another type of steel — which has almost the same amounts of carbon, manganese and silicon, but also contains tiny amounts of niobium (about 0.03% in weight) — increases the material’s strength and toughness4. Niobium-microalloyed steel is slightly more expensive than conventional steel. But because it is stronger, less material is required4,5, lowering the total cost of a building. Reducing steel consumption can also reduce CO2 emissions4,5 by some 20%.

Air taxis will soon be in our skies — if batteries can be made safer

Researchers are investigating other substitutions, too. For example, rare-earth magnets, which require elements such as dysprosium or terbium, could be replaced with less environmentally damaging ones based on iron nitride6. And sodium-ion batteries7 could replace lithium-ion ones to circumvent lithium’s global supply limitations, high extraction costs and the environmental damage it causes during extraction. Scientists are also studying thermal batteries that store energy as heat rather than as electricity and that are made from materials such as cement and crushed rock.

To accelerate the adoption of materials with lower carbon footprints, governments should update policies and regulations. Governments and industry can also create certification schemes that reward low-emission material choices, helping designers, engineers and consumers to make informed decisions. And universities should include substitution principles in engineering and materials education, to train a workforce to select materials that have a minimal environmental impact, not just high performance.

Academia and industry must work together closely, through industry-funded fellowships, joint research programmes and institutions such as the US Engineering Research Centers, which are supported by the National Science Foundation.

Adopt green technologies

The metal-production industry urgently needs to reduce its environmental impact. Aluminium production, for example, is responsible for around 270 million tonnes of CO2 a year (one-tenth that of steel). It also releases toxic fluorine-containing species, which are powerful greenhouse gases. And copper smelting releases large amounts of sulfur dioxide, contributing to acid rain.

Green manufacturing technologies that lower emissions are needed. Many exist already. For instance, a top gas recycling blast furnace that reuses carbon dioxide from the ironmaking process can reduce emissions substantially8. Other harmful by-products can also be upcycled. In copper smelting, for example, sulfur dioxide can be converted into usable compounds, such as sulfuric acid.

Battery prices are falling, so why are electric cars still so expensive?

Innovations in hydrometallurgy and bioleaching9 that use microorganisms to break down the minerals in ores and release pure metals are revolutionizing extraction. They can take nickel, copper and gold from ores with low concentrations of these elements and avoid energy-intensive smelting procedures, enabling metal extraction from sources that were previously too expensive to mine or dismissed as unusable, such as by-products of mining and other industrial processes and electronic waste.

However, in practice, many of these advanced technologies are not being adopted because of their cost. Governments must help businesses and individuals through policies or incentives, such as low-interest loans, investment grants and carbon pricing mechanisms. Solar energy promotion shows how government incentives can accelerate adoption despite high upfront costs. The US Investment Tax Credit and state-level programmes can offer subsidies, zero-interest loans and community solar-energy support.

Go circular

Another way to lower metal consumption is to improve the durability, repairability and recyclability of metal-containing products. Companies should design long-lasting products and offer end-of-life recycling. Several corporations, including technology giants Apple and Dell, have adopted circular practices through certified refurbishment programmes.

Six roadblocks to net zero — and how to get around them

Governments must support these efforts by overseeing recycling data, enforcing disclosure requirements and setting up recycling and waste-management incentives10. The European Union has embraced this approach. For example, its Circular Economy Action Plan and its Ecodesign directive mandate standards for the durability and repairability of products. International organizations should standardize practices and environmental agencies or independent bodies must monitor compliance and progress. The International Organization for Standardization has issued standards on ecodesign and design for disassembly. The United Nations Environment Programme’s International Resource Panel and the Organisation for Economic Co-operation and Development provide guidance for sustainable material flows11.

Accelerating metal recycling must also be a top priority. Steel, aluminium and copper are already recycled widely, but urgent improvements are needed for others, such as nickel, cobalt, manganese and rare-earth elements. Advanced sorting methods and urban mining programmes12 that can recover valuable metals from electronic waste are crucial.

In 2021, for example, Japan’s Ministry of Economy, Trade and Industry outlined the country’s transition to a circular economy. According to the nation’s economic and environmental ministries, some 15 million home appliances were collected nationwide in the 2021 fiscal year.

Manufacturing processes can be improved, too. 3D printing, for example, reduces waste by building objects layer by layer, using only the necessary amount of raw metal powder13.