To produce enough ‘critical metals’ such as copper, lithium and nickel to support the green-energy transition, the mining industry needs to boost operations two-to-fivefold worldwide by 20501. Geopolitical tensions, environmental damage and social conflicts will constrain this growth2. But another threat needs much more attention: climate change.

Extraction of the very metals needed to address global warming will be increasingly impeded by the extreme weather that accompanies climate change.

Thousands of critical-mineral mines are in sensitive environments, including deserts in Africa, highlands in the Andes and coastlines across the Asia-Pacific. Mining areas are already regularly exposed to hazards. In 2023 alone, wildfires forced Canadian mines to suspend operations, extreme rainfall flooded pits and cut off access roads in Australia, and ongoing drought in Chile threatened regional water supplies, mining operations and local communities3.

How the rush for critical minerals is neglecting human needs

The costs of such damage are growing as the planet warms. For example, over the past decade, excessive rainfall has led to losses of around Aus$3 billion (US$2 billion) for Australian copper mines (see Supplementary information). Under ‘business as usual’ production, without undertaking climate adaptation measures, the industry stands to lose Aus$7.5 billion as a result of heavy precipitation alone between now and 2050, equating to 50,000 tonnes of copper that could be used for energy-transition technologies.

The consequences of mining disruptions will spiral across the global economy. Constrained supplies will mean that the energy transition is slower than projected. Mining communities and ecosystems will come under increasing strain3. An energy transition that ignores these threats will risk deepening social divides, undermining community trust and jeopardizing long-term sustainability.

As the United Nations COP30 climate summit gets under way in Belém, Brazil, we call for more investment and planning to strengthen the resilience of critical-mineral supply chains. Steps include systematic reviews of climate hazard exposure, anticipation of future risks, and improved management of mining sites and their surroundings. Towards that end, we outline four key strategies.

Plug data gaps

To gauge risks, researchers first need to understand the mines themselves: where they are located, their scale and their landscapes, as well as production rates and physical inputs and outputs4. The details of how assets, such as dams for waste ‘tailings’, were built are also essential for assessing the risk of catastrophic failures5. Yet all these details are documented for fewer than half of mines, owing to under-reporting, the prevalence of small-scale operations and commercial or regulatory barriers that limit transparency or data standardization4. Mining companies need to generate and share data (covering production quantities, mineral by-products, resource inputs, supply chains and asset construction, for example) to help researchers to fill global data gaps.

The vulnerabilities of infrastructure networks to climate hazards need to be assessed. Mines rely on water, fuel, electricity, railways, smelters, processing facilities and ports. In Chile, for example, copper production competes with the needs of communities and the environment in terms of water supplies6. To map the environment, baseline information needs to be collected on biodiversity, catchment hydrology and long-term water-quality trends. But again, such data and modelling are scarce.

Over the coming decades, African mines will face scores of days that exceed heat-safety levels each year. Credit: Cynthia R Matonhodze/Bloomberg via Getty

What’s more, the resilience of mining communities to extreme weather or dam bursts, for example, must be evaluated and adaptation plans developed accordingly. People’s preparedness, strengths and cultural practices influence how they manage hazards. Governance and economic systems, including the approval process for mining, environmental monitoring and health-and-safety standards, determine the extent to which risks can be anticipated and addressed. Public infrastructure, disaster planning and training can help people to cope during emergencies.

Operators and researchers also need to look at how climate shapes and compounds the hazards to mines. Historical records of temperature, rainfall, storms and droughts can reveal how hazards have already shaped operations. Sharing lessons from previous adaptation actions across the industry can help mining sites to prepare for future risks.

Looking further ahead, climate models can be used to project extremes of precipitation and temperature over the coming years and decades, even beyond a mine’s operating life. Access to modelling capacity and observational data varies globally, often to the detriment of low-income regions, which often lack the infrastructure to monitor and forecast the weather7.

Metals are key to the global economy — but three challenges threaten supply chains

Compiling all this knowledge, which can be challenging even for a single mine, requires more than open-access data sets. Information is fragmented across governments, companies, communities and researchers, and spans disciplines ranging from climate science and engineering to logistics and the social sciences. These silos obstruct resilience in the mining industry, as reports from the UN Environment Programme3 and the International Finance Corporation8 (part of the World Bank Group) highlight.

The solution lies in integration: communication across climate and hazard science, engineering and operations, governance, communities and environmental systems9. Independent scientists need to be embedded within mining-company operations to ensure that climate data are communicated effectively. Mine operators also need to connect with communities for adaptation planning.

Shared platforms need to be built, common indicators developed and equitable access to expertise assured. This will require more funding for climate scientists in industry, and for mining companies to build community resilience into their sustainability practices. The first step is for researchers and the mining industry to jointly undertake site-specific climate-risk analysis.

Address known risks

Although issues around corporate reporting limit the extent to which researchers can assess the entire critical-minerals sector8, the information that is already available points to troubling patterns that require action. Funding clearly needs to be put in place to help the mining sector adapt to threats from climate change.

To get a sense of what the risks are, we examined climate projections for a representative set of 1,642 medium- and large-scale mines around the world that produce minerals needed for energy-transition technology (see Supplementary information for analysis). Sites were drawn from the International Council on Mining and Metals’ public database, and climate data from the Intergovernmental Panel on Climate Change’s Coupled Model Intercomparison Project10.

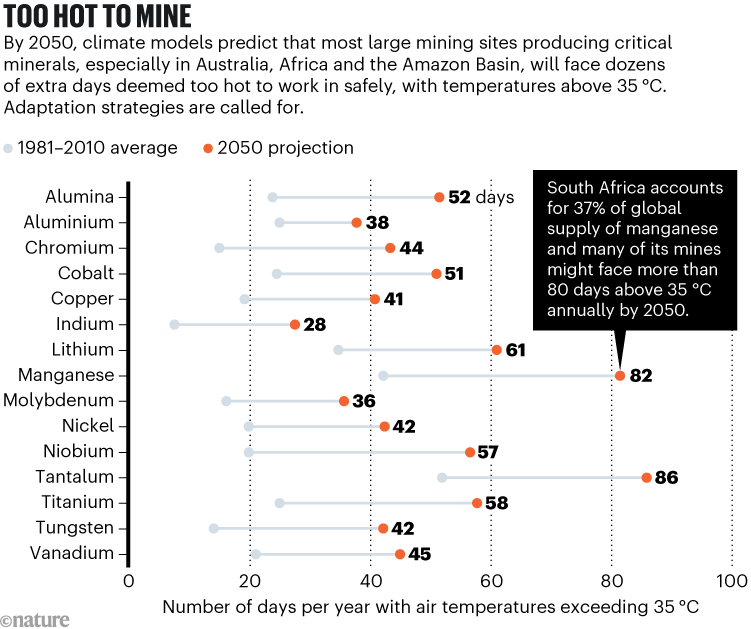

Heat is one problem (see ‘Too hot to mine’). By 2050, 90% of mining sites are predicted to face increasing temperatures. The number of days per year deemed hazardous for human health (with temperatures exceeding 35 °C) will rise, particularly in areas that already contend with extreme heat, such as the Australian outback, Africa and the Amazon Basin.

Analysis by T. Savige et al.

For example, South Africa is the world’s leading producer of manganese (used in lithium-ion batteries), accounting for 37% of global supply. Most manganese mines in central and northern parts of the country are predicted to experience more than 80 days per year above 35 °C by 2050.

Health-and-safety measures will be needed to minimize heat-related illness for workers, such as reductions in shift durations or limiting outdoor work during peak heat. And this will lower production, unless adaptation strategies are put in place or other mines come online elsewhere.

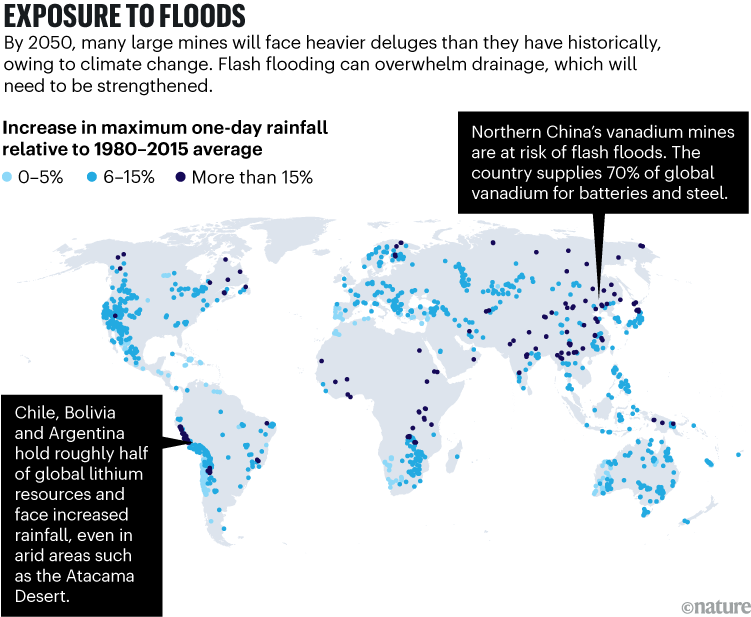

Storms and extreme rainfall are also projected to increase overall. By 2050, annual precipitation levels are expected to rise at three in five (62%) of the sites we examined, notably mines across the central Andes in Peru, Bolivia and northern Argentina, including in areas historically thought of as being water-scarce.

Flash floods might also curb mining operations (see ‘Exposure to floods’). Almost all (94%) of the sites we examined would see an increase in one-day maximum precipitation. Vanadium mines in China are particularly exposed, facing, on average, a 16% increase in their one-day maximum precipitation. Around 70% of the world’s vanadium, used in grid-storage batteries and high-strength steel, is supplied by China, with much of it coming from the environs of one city, Panzhihua.

Source: Analysis by T. Savige et al.

More detailed research is needed to form the basis of adaptation plans. Climate hazards are challenging to predict locally, and climate models need to be continually updated with the latest data, scaled appropriately to account for topography, and grounded with site-specific knowledge to produce the most accurate forecasts possible for each site7. The depth of knowledge needed calls for stronger links between researchers and mining companies. Sustaining this across the sector will require international research funding and collaboration, as well as building partnerships with community groups.

Ample funding is available: a mine can attract billions of dollars in investments before delivering a return. If adaptation research received funds amounting to a modest percentage of the industry’s projected losses due to climate change, that could lower the costs of damage and operational downtime for mining companies and protect the energy transition.

Embed climate risk assessments

Governments and mining companies need to adapt how mines operate. This means integrating climate knowledge into every stage: exploration, planning, construction, production, closure and rehabilitation.

For example, the Escondida mine, located at altitude in the arid Atacama desert in Chile, produces about 5% of global copper supply, and is expected to be operational until 2080. To ensure its water supply, Escondida invested US$3.4 billion in a desalination plant producing 215,000 cubic metres of water per day, transported from the coast up to the mine (see go.nature.com/49e9hyd).