Fabrication of thin liquid layer on filter media

Non-volatile, low surface tension tri-methylsiloxy-terminated PDMS (for example, silicone oil) was used for the thin liquid coating. Because the silicone oil can uniformly form a thin layer on a PDMS brush-grafted surface because of minimized interfacial energy, we prepared the PDMS brush onto the surface of filter media. Before the PDMS grafting, surface oxidation was initially performed using a UV–ozone cleaner (AhTech LTS), emitting ultraviolet light at a wavelength of 254 nm with an intensity of 20 mW cm−2, for 15 min. Then, a solution including dimethyldimethoxysilane (96%, Gelest) and sulfuric acid (98%, Daejung Chemicals) dissolved in methanol (99.5%, Samchun Chemicals), weight ratio of 10:1:100, was sprayed onto the oxidated substrate. After evaporation of the solvent, the PDMS brush was synthesized from the surface hydroxyl groups by grafting from reaction. After the surface polymerization, residual unreacted chemicals were washed away using methanol. The presence of the grafted PDMS brush on various filter surfaces was confirmed by X-ray photoelectron spectroscopy (XPS) (K-alpha+, Thermo Fisher Scientific).

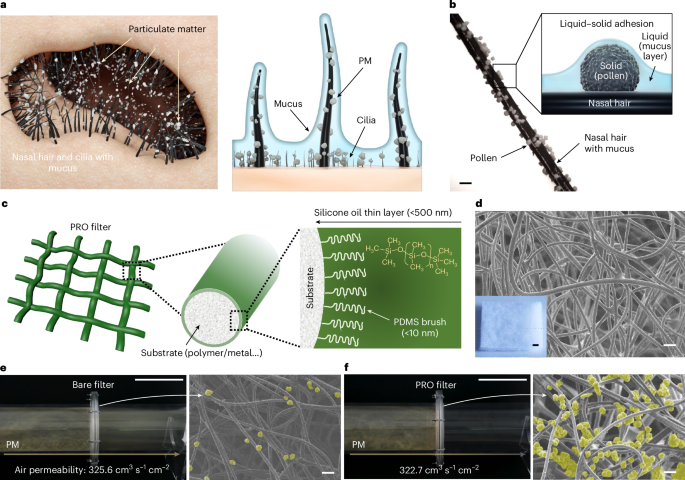

On the PDMS brush-grafted filter media, silicone oil (Gelest) solution in hexane (99.5%, Sigma Aldrich) was sprayed by using a spray gun equipped with a 0.35-mm nozzle at a pressure of 0.5 mPa. To remove residual hexane, the samples were dried at room temperature for 24 h. Then, hexane negligibly remained because of its high volatility. Silicone oil was spread over the surface of the fibres, realizing the PRO filter. To verify the incorporation of silicone oil within the filter media, an energy-dispersive X-ray spectroscopy analysis was conducted using a field-emission scanning electron microscope (FE-SEM) (SIGMA, Carl Zeiss).

Adhesion force analysis

The interaction between the spherical particle and a planar substrate was quantified using colloidal probe AFM (NanoWizard, JPK Instruments). Silica (about 7 μm and 15 μm) and polyethylene beads (around 15 μm, Cospheric) were used as probe particles, which were glued onto the edges of tipless cantilevers (MikroMasch) using epoxy glue. Before adhering the particle to the cantilever, the spring constant and sensitivity value of the cantilever were calibrated using a non-contact method. The force–distance curves were measured three times for each sample with a working speed of the cantilever of 2 μm s−1.

For consistent analysis, adhesion was measured on planar samples. Cover glass (VWR Chemicals) was adopted as a substrate. Oil-coated substrate was prepared using a spin coater (ACE-200, iNexus) at a speed of 4,000 rpm for a duration of 60 s. The thickness of the silicone oil layer was varied by using different concentrations of silicone oil solution in n-hexane (95%, VWR Chemicals).

The force–distance curve, ascertained by observing cantilever deflection, allowed for the quantification of these forces. Extended Data Fig. 3 shows the basic methodology for analysing force–distance curves, specifically in measuring the behaviour at solid–liquid interfaces. The analysis consisted of a sequence of steps: (1) approaching the lubricated surface; (2) contact with the lubricant; (3) penetrating the lubricant; (4) touching the glass substrate, thereby showing lubricant thickness; (5) pushing the cantilever until it reached the artificial force limit; (6) retracting from the substrate with a meniscus; and (7) detachment of the probe. We initiated direct contact between the probe and the solid substrate because of the thinness of silicone oil, making interfacial contact with the lubricant unfeasible. We pressed the probe to its force threshold after contact with the solid surface to standardize the contact depth with the solid substrate.

Imaging of interface between substrate and particle

A confocal microscope (Leica SP8, Leica) was used to visualize the particles attached to planar substrates. A spherical silica particle (Duke Scientific) with a diameter of about 105 μm was used for these observations. Perylenediimide dye was applied within the silicone oil to observe the silicone oil meniscus surrounding the particle.

Characterization of filtering performance

FE was measured using a custom-built air filter testing chamber that complies with the specifications delineated in the global testing standard: DIN 71460-1:2006. To validate the reliability of the custom-built air filter testing chamber, cross-validation of efficiency measurement with a certified testing agency (KITECH) was performed (Supplementary Fig. 5). Identical testing standards and test conditions were applied in both set-ups to ensure consistency and comparability. FE was determined according to the equation \({\rm{FE}}=\frac{{C}_{{\rm{b}}}-{C}_{{\rm{a}}}}{{C}_{{\rm{b}}}}\times 100\), where Cb and Ca denote the PM concentrations before and after filtration, respectively. A2 fine standard test dust, briefly called A2 dust (Powder Technology), with a predominant size distribution diameter of 0.3–10 μm, was selected as test PM. A particle generator (SAG 410, TOPAS) consistently injected the A2 dust into the chamber. For each test, 90 mg of A2 dust was introduced. Quantitative measurement of airborne particles was taken using a particle counter (11-A, GRIMM) that can measure particle sizes ranging from 0.25 μm to 32 μm in diameter. FEs were categorized into three sizes based on PM diameters: PM1.0 (0.3–1 μm), PM2.5 (1–2.5 μm) and PM10 (2.5–10 μm).

Moreover, the pressure drop (ΔP) across the filtration system was monitored using a pressure gauge (PTA202D, SCS). The threshold for the pressure gauge in our system was approximately 2,500 Pa because of fan operation limit. The system was programmed to automatically modulate the face velocity by adjusting the airflow rate in response to observed elevations in ΔP, monitored using a flow meter (CP213, KIMO). The working area of FE test was selected as 100 cm2. The electrostatic charge present on the filter media was neutralized before the measurements. To evaluate the filtering performance, the quality factor (QF) was calculated by combining FE and ΔP as follows: \({\rm{QF}}=-\frac{{\rm{ln}}(1-{\rm{FE}})}{\Delta P}\) (Supplementary Fig. 7). The weight of captured PM on filters was measured to intuitively compare the filtering performance by comparing the weight before and after filtration (Supplementary Fig. 22).

Various conventional filters, including pre-filters, medium filters and HEPA filters made of non-woven polyester, polypropylene and polyvinylidene fluoride (PVDF) were used as test filter media. Media of various materials with different pore structures, such as melamine foam, nickel foam, and woven fabrics made of cotton and hemp, were also applied. Pore structure of each filter media was measured using SEM (Supplementary Fig. 6). Air permeability of the filter media was measured using an air permeability meter (ADE-580A, AND), in accordance with ASTM D737, involving a pressure of 125 Pa over an area of 38 cm2.

Effect of oil viscosity

To provide optimal viscosity of silicone oil layer for filtration, the effect of oil viscosity on the particle adhesion and the FE was investigated. Initially, we tested the adhesion force with varied viscosities of silicone oil: 100 cSt, 1,000 cSt, 5,000 cSt and 10,000 cSt (Extended Data Fig. 4a). Film thickness was fixed as 200 nm and approximately 15 μm silica bead was selected as reference probe. The probe approached the oil-coated glass substrates and moved until it touched for 500 nN of load. Then, the probe retracted from the substrate. The working speed of the cantilever was fixed at 2 μm s−1. Furthermore, we tested the effect of oil viscosity on filtering performance at 2 m s−1 of face velocity (Supplementary Fig. 16). A polyester and polypropylene filter were used, and approximately 10 g m−2 of silicone oil was applied to synchronize other conditions. A detailed discussion of the effect of oil viscosity on filtering performance is provided in Supplementary Information section 4.

PM resuspension

To visualize the PM resuspension, a high-speed camera (FASTCAM SA6, Photron) operating at 1,000 frames per second was used (Fig. 3e,g). Nitrogen gas was blown by an air gun from the opposite direction to the A2 dust-capturing polypropylene non-woven filter. A piece of paper was positioned in front of the filter media as an indicator to confirm the blown gas through the filter. PM adhesion properties of filters during resuspension test were observed through SEM (Supplementary Fig. 20). Quantitative analysis of PM detachment was tested by placing the particle counter in front of PM-filtered filters during resuspension (Supplementary Fig. 21). Furthermore, PM resuspension in wide perspective was measured using digital camera (EOS D80, Canon) under blue light (Supplementary Fig. 23). Nitrogen gas was also blown by air gun from the opposite direction to the A2 dust captured polyester non-woven filter.

Multidirectional filtration

Multidirectional filtration characteristics were tested under (1) bidirectional filtration, (2) random airflow and (3) natural winds. Initially, to quantitatively analyse multidirectional filtration, we measured the weight of filtered PMs after a filtration test at a face velocity of 2 m s−1. Then, we performed another filtration test in the opposite direction by flipping the filter in the chamber and measured the weight of filtered PMs. Furthermore, we demonstrated filtration under random airflow (Supplementary Fig. 24). We prepared a sculpture made of the PRO filter in a closed chamber and filled the space with A2 dust using a particle generator. Random airflow was generated by fans on four sides in the chamber. After the filtration under random airflow, the filtered PM on the PRO sculpture was imaged using SEM. Moreover, multidirectional filtration was tested under natural winds. We integrated filter holders in the outdoor smoking area and installed PRO filters without an external fan. After the filtration for 38 months, we captured photos and SEM images of both bare and PRO filters.

Characterization of particle packing behaviour by silicone oil

Polyester fibre with a diameter of 75 μm was used to observe the particle packing behaviour on the thin silicone oil layer. A single stretched fibre was installed in the filter testing chamber, then PM was deposited on the fibre. After the deposition, silicone oil with a viscosity of 100 cSt was dropped at the edge of the fibre. Then, the particle packing behaviour was observed using an optical microscope (S39B, Microscopes). The effective thickness (teff) of PM was measured using ImageJ by taking the fibre diameter from the average thickness of the dust deposited polyester fibre.

Furthermore, the changes in pore size in the filter were measured using stainless steel metal mesh. Images before and after filtration of the metal mesh were captured using an optical microscope. The projected pore area was measured through ImageJ using the size analyser feature, then six pores were averaged.

Energy consumption of the ventilation system

Calculation of electricity consumption from the ΔP–deposition time curve was done using the equation in the ventilation standard: SPS-KACA-0026-7175:2017 (Supplementary Fig. 25). Energy consumption of ventilation is expressed as \(W=\frac{{Q}_{{\rm{v}}}\Delta \bar{P}t}{\mathrm{1,000}\eta }\), where Qv is the airflow of ventilation, η is fan efficiency and t is the operation time. An airflow rate of 0.9 m3 s−1 and a fan efficiency of 0.5 were used following the ventilation standard. The operation time was selected as 27 min based on the moment at which the ΔP across the bare pre-filter and HEPA filter (orange line) doubled its initial value.