A Qantas Airbus A380 flew 34 times while a 4-foot-1-inch nylon tool — used to turn the engine’s intermediate-pressure compressor during borescope inspections — was wedged inside one of its Rolls-Royce Trent engines. It logged 294 flight hours between December 6, 2023 and January 1, 2024, but the news became public this week.

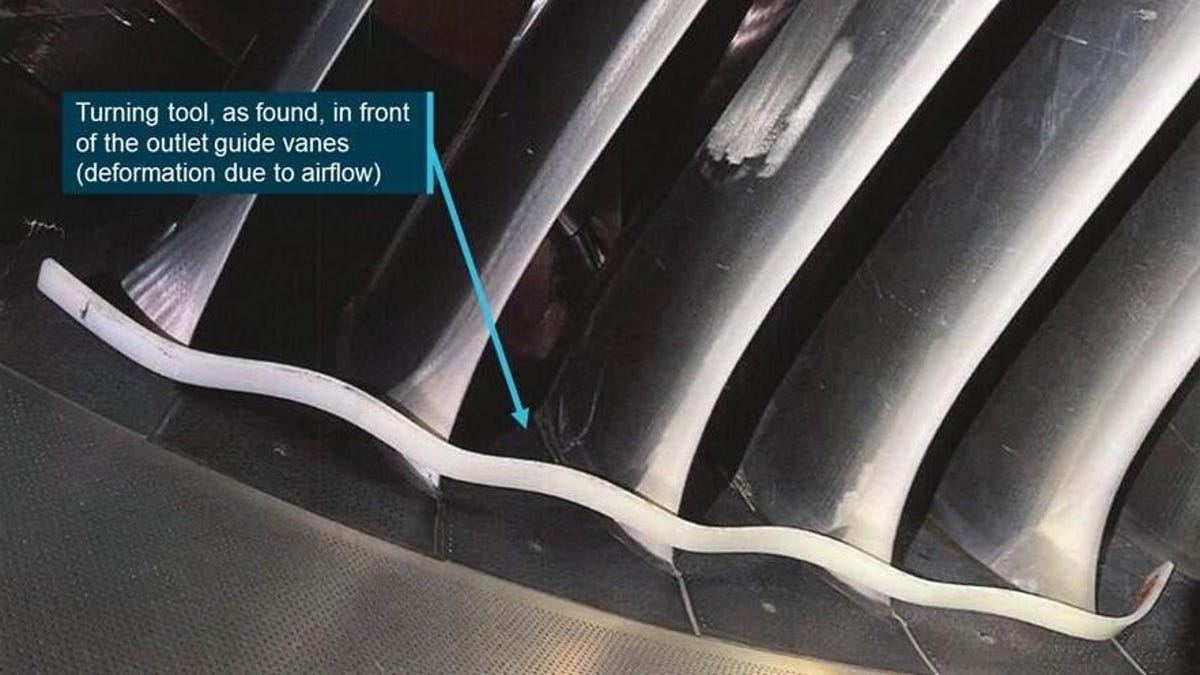

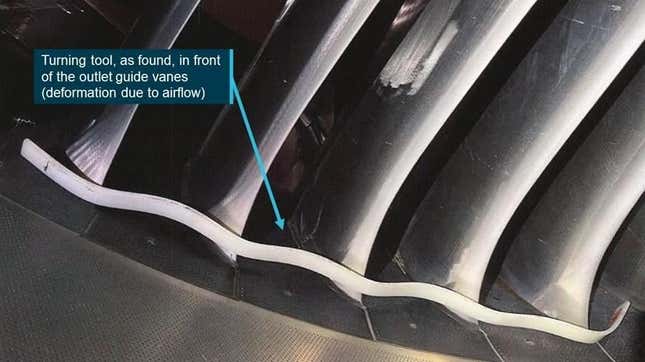

Investigators at the Australian Transport Safety Bureau determined that the tool was left in the engine during previously scheduled maintenance in Los Angeles in December of 2023. Luckily, over the 34 flights the engine and plane were never damaged, but the tool was deformed by high energy flow. Apparently, maintenance engineers somehow didn’t notice the tool had been left in the engine’s low-pressure compressor case while they conducted checks for foreign objects after finishing their borescope inspection test.

To make things even more troubling, maintenance engineers in LA realized it was missing, but they didn’t conduct a “lost tool procedure” after that. A spokesperson for the ATSB said, “the certifying engineer released the aircraft for service with the tool unaccounted for.” It flew all the way back to Melbourne without incident. Don’t worry, though. After the tool was found, Qantas Engineering immediately briefed staff on the importance of making sure all tools are where they should be after completing a tast.

“Foreign object debris and damage can pose a significant threat to the safe operation of aircraft, which is why regulations, procedures and training are in place to limit the risk of foreign object damage, especially from introduced objects during maintenance, ATSB Chief Commissioner Angus Mitchell said. “Correctly applying tool control is fundamental to mitigating against any human errors that may arise.”

Head over the the ATSB’s website for an almost minute-by-minute breakdown of how this massive error occurred as well as an in-depth look at the proper procedures to make sure stuff like this doesn’t happen. It’s pretty damn interesting.