Batteries are already powering electric vehicles (EVs) on our roads. But they are yet to transform aviation. Although some electric passenger planes are being prototyped, commercial uses are a decade away. The low-altitude economy is, however, an emerging test bed for electric propulsion flight technologies, which must operate in conditions and to safety standards that are very different from those on land.

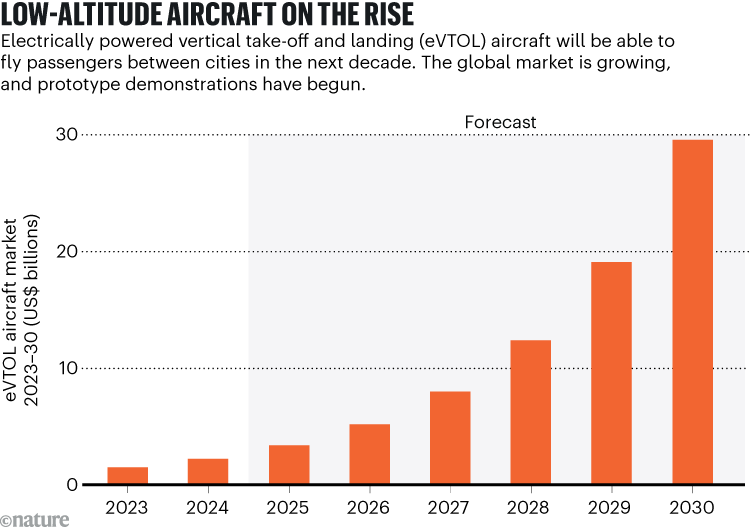

Drones operating at altitudes below 1,000 metres are eyed as affordable ways to transport small quantities of goods and speed up logistics. Larger electric vertical take-off and landing (eVTOL) aircraft promise to transform how people travel around cities. The global market for eVTOL aircraft could reach US$30 billion by 2030, analysts project, driven by applications in emergency response, logistics, air taxis and tourism (see ‘Low-altitude aircraft on the rise’).

Battery prices are falling, so why are electric cars still so expensive?

China has included the low-altitude economy in its 2024 government work report and tasked a department to support the development of it (see go.nature.com/3jbwywr). Uncrewed drone deliveries now operate in the city of Shenzhen, China, and designs for autonomous air taxis are being tested. For example, in February last year, an uncrewed passenger eVTOL aircraft successfully flew 50 kilometres between Shenzhen and Zhuhai in 20 minutes — a journey that would have taken 3 hours by car. The air taxi, developed by electric-aircraft company AutoFlight based in Shanghai, China, and Augsburg, Germany, has a maximum take-off weight of 2.4 tonnes and can carry five passengers. Companies in North America, Europe, Japan and beyond are also developing low-altitude aircraft.

It is an exciting time in this nascent field, which is exploring how best to combine state-of-the-art energy supplies, motors, chips and avionics. But, as more low-altitude craft take to our skies, careful management and regulation of these systems will be crucial, to ensure their safety as well as public trust. Here we outline the challenges and regulatory needs for energy supplies for low-altitude aircraft.

Source: go.nature.com/422EN3U

Challenges of battery technology

To avoid contributing to climate change, the low-altitude economy must develop in tandem with the low-carbon economy. Just as the goal for clean-energy road transport could be achieved by powering EVs with renewable electricity, eVTOL taxis might similarly run on power from solar and wind sources.

But, so far, only a few prototypes have been realized1,2. Solar-powered drones, such as AtlantikSolar developed at the Swiss Federal Institute of Technology (ETH) in Zurich, have managed to optimize the energy balance between solar panels and batteries to achieve several days of continuous flying1. By covering big wings with solar cells, large solar-powered aircraft have flown for weeks at a time in the stratosphere.

The small-drone revolution is coming — scientists need to ensure it will be safe

To do more, reliable and robust sources of electrical energy are needed. EVs have driven remarkable advancements in the development of lithium-ion batteries over the past decade3. Yet the transition from roads to skies is far from straightforward.

Airborne operations impose radically different constraints: greater sensitivity to weight, the need for rapid bursts of power during take-off, landing and manoeuvring, and an uncompromising need for tolerating faults. A failure on the ground might be an inconvenience. A failure in the air can be fatal.

EV batteries, although reliable for terrestrial use, are too heavy, low-powered and frail for aviation. Safety is the most unforgiving requirement4. To power flight safely, batteries must meet standards that exceed those of EVs and even some space missions. Civil aviation demands zero tolerance for in-service failures. Uncontrollable overheating of a battery, and a potential fire or explosion, in mid-air is not survivable.

Aviation-grade batteries must therefore be designed with multilayer containment, real-time fault detection and thermal isolation. Unlike EVs, which rely on relatively stable discharge rates, aerial platforms demand quick boosts of power that can exceed the battery’s rated output, and that must be sustained without degradation or thermal instability.

Meeting such demands under tight weight and volume constraints requires advanced cell chemistry and battery-management systems that are capable of running analytics and balancing loads in milliseconds. Promising examples include an aviation battery (which achieves 500 watt-hours per kilogram) from Chinese battery manufacturer CATL, which announced a partnership with AutoFlight for eVTOL flights. It is currently in the development and certification stage. Adaptive battery-management systems dynamically adjust operational parameters according to the flight conditions5.

A cleaner future for flight — aviation needs a radical redesign

Lessons can be drawn from EV battery designs6. For example, solid- and semi-solid-state batteries offer higher energy density and enhanced safety compared with conventional lithium-ion batteries and might be suitable choices for aircraft7. Nanostructured materials (such as nanowires) might offer improved energy density and charging and discharging rates8. Hydrogen fuel cells are another option9, although they remain in the early stages of commercialization.

Although all-electric drones are already in operation at some drone-delivery companies, scaling up to passenger aircraft remains a long way off. In the short term, hybrid-electric systems that combine conventional engines for cruising with electric motors for high-power phases, such as take-off, landing and climbing, are emerging as a practical way to bridge the gap. Examples include an aircraft called Electric EEL, developed by aerospace company Ampaire in Long Beach, California, which is currently in flight trials for commuter routes, and the ES-30 made by aviation manufacturer Heart Aerospace in El Segundo, California, which is planned to enter service in 2028.

In pursuit of improving energy-storage capacity and reducing weight, fresh aircraft concepts are exploring structural batteries, in which energy storage is embedded directly into the airframe, such as in the wings or fuselage panels. This approach blurs the conventional separation between aero-structures and energy systems, meaning that a crash or repair could affect both at once, and the usual design rules and maintenance practices no longer apply. Proving that such designs are safe will require tests in materials science, structural dynamics and airworthiness.