Hou, H., Qian, S. & Takeuchi, I. Materials, physics and systems for multicaloric cooling. Nat. Rev. Mater. 7, 633–652 (2022).

Abas, N. et al. Natural and synthetic refrigerants, global warming: a review. Renew. Sustain. Energy Rev. 90, 557–569 (2018).

Qian, S. et al. High-performance multimode elastocaloric cooling system. Science 380, 722–727 (2023).

Zhou, G., Zhu, Y., Yao, S. & Sun, Q. Giant temperature span and cooling power in elastocaloric regenerator. Joule 7, 2003–2015 (2023).

Ghaddar, N. et al. Sustainable cooling solutions. One Earth 7, 1315–1319 (2024).

Esper, J. Torbenso, M. & Büntgen, U. 2023 summer warmth unparalleled over the past 2,000 years. Nature 631, 94–97 (2024).

International Energy Agency (IEA). The Future of Cooling: Opportunities for Energy-Efficient Air Conditioning (OECD/IEA, 2018).

Garimella, S. et al. Realistic pathways to decarbonization of building energy systems. Joule 6, 956–971 (2022).

Aphornratana, S. & Sriveerakul, T. Analysis of a combined Rankine–vapour–compression refrigeration cycle. Energy Convers. Manage. 51, 2557–2564 (2010).

Mañosa, L. & Planes, A. Materials with giant mechanocaloric effects: cooling by strength. Adv. Mater. 29, 1603607 (2017).

Zhang, Y. et al. Rare-earth-free Mn30Fe20-xCuxAl50 magnetocaloric materials with stable cubic CsCl-type structure for room-temperature refrigeration. Adv. Funct. Mater. 33, 2310047 (2023).

Han, D. et al. Molecular interface regulation enables order-disorder synergy in electrocaloric nanocomposites. Joule 7, 2174–2190 (2023).

Cui, J. et al. Demonstration of high efficiency elastocaloric cooling with large ΔT using NiTi wires. Appl. Phys. Lett. 101, 073904 (2012).

Jacobs, S. et al. The performance of a large-scale rotary magnetic refrigerator. Int. J. Refrig. 37, 84–91 (2014).

Balli, M. et al. A pre-industrial magnetic cooling system for room temperature application. Appl. Energy 98, 556–561 (2012).

Franco, V. et al. Magnetocaloric effect: from materials research to refrigeration devices. Prog. Mater Sci. 93, 112–232 (2018).

Mañosa, L. & Planes, A. Solid-state cooling by stress: a perspective. Appl. Phys. Lett. 116, 050501 (2020).

Cazorla, C. Novel mechanocaloric materials for solid-state cooling applications. Appl. Phys. Rev. 6, 041316 (2019).

Zhao, D. et al. Subambient cooling of water: toward real-world applications of daytime radiative cooling. Joule 3, 111–123 (2019).

Pattanaik, M. et al. A self-regulating multi-torus magneto-fluidic device for kilowatt level cooling. Energy Convers. Manage. 198, 111819 (2019).

Bruederlin, F. et al. Elastocaloric cooling on the miniature scale: a review on materials and device engineering. Energy Technol. 6, 1588–1604 (2018).

Bruederlin, F. et al. SMA foil-based elastocaloric cooling: from material behavior to device engineering. J. Phys. D Appl. Phys. 50, 424003 (2017).

Greibich, F. et al. Elastocaloric heat pump with specific cooling power of 20.9 W g−1 exploiting snap-through instability and strain-induced crystallization. Nat. Energy 6, 260–267 (2021).

Ahčin, Z. et al. High-performance cooling and heat pumping based on fatigue-resistant elastocaloric effect in compression. Joule 6, 2338–2357 (2022).

Tusek, J. et al. A regenerative elastocaloric heat pump. Nat. Energy 1, 16134 (2016).

Engelbrecht, K. et al. A regenerative elastocaloric device: experimental results. J. Phys. D Appl. Phys. 50, 424006 (2017).

Kabirifar, P., Trojer, J., Brojan, M. & Tušek, J. From the elastocaloric effect towards an efficient thermodynamic cycle. J. Phys. Energy 4, 044009 (2022).

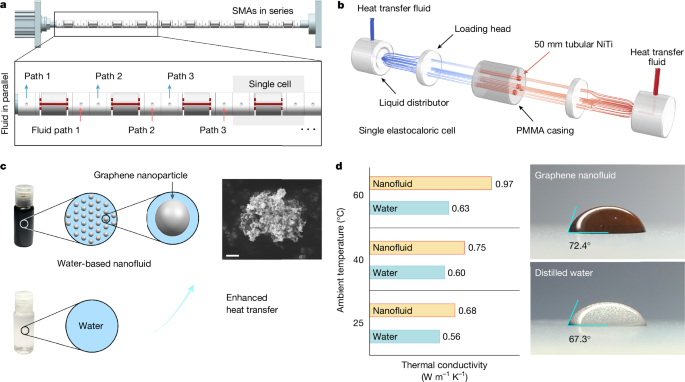

Loulijat, H. & Moustabchir, H. A study of the effects of graphene nanosheets on the thermal conductivity of nanofluid (argon-graphene) using reverse nonequilibrium molecular dynamics method. Int. J. Thermophys. 42, 125 (2021).

Pavia, M., Alajami, K., Estellé, P., Desforges, A. & Vigolo, B. A critical review on thermal conductivity enhancement of graphene-based nanofluids. Adv. Colloid Interface Sci. 294, 102452 (2021).

Gupta, S. S. et al. Thermal conductivity enhancement of nanofluids containing graphene nanosheets. J. Appl. Phys. 110, 084302 (2011).

Zhu, Y., Zhou, G., Cheng, S., Sun, Q. & Yao, S. A numerical study of elastocaloric regenerators of tubular structures. Appl. Energy 339, 120990 (2023).

Zhu, Y. et al. Modelling of elastocaloric regenerators with enhanced heat transfer structures. Int. J. Heat Mass Transfer 176, 121372 (2021).

Zhou, G. et al. A multi-material cascade elastocaloric cooling device for large temperature lift. Nat. Energy 9, 862–870 (2024).

Velders, G. J. M. et al. Projections of hydrofluorocarbon (HFC) emissions and the resulting global warming based on recent trends in observed abundances and current policies. Atmos. Chem. Phys. 22, 6087–6101 (2022).

Kawarada, Y. et al. Abnormal grain growth of 68Cu-16Al-16Zn alloys for elastocaloric cooling via cyclical heat treatments. J. Phys. Energy 5, 024012 (2023).

Li, Y. et al. Energy-efficient elastocaloric cooling by flexibly and reversibly transferring interface in magnetic shape-memory alloys. ACS Appl. Mater. Interfaces 10, 25438–25445 (2018).

Zhang, Y. et al. Solid-state cooling with high elastocaloric strength and low driving force via NiTi shape memory alloy helical springs: experiment and theoretical model. Mech. Mater. 178, 104575 (2023).

Hartquist, C. et al. An elastomer with ultrahigh strain-induced crystallization. Sci. Adv. 9, eadj0411 (2023).

Li, X. et al. Continuous and efficient elastocaloric air cooling by coil-bending. Nat. Commun. 14, 7982 (2023).

Zhang, K. et al. Interactions among phase transition, heat transfer and austenite plasticity in cyclic compression of NiTi shape memory alloys: effect of loading frequency. J. Mech. Phys. Solids 191, 105782 (2024).

Yin, H., He, Y. & Sun, Q. Effect of deformation frequency on temperature and stress oscillations in cyclic phase transition of NiTi shape memory alloy. J. Mech. Phys. Solids 67, 100–128 (2014).

Deng, Y. et al. Low-melting-point liquid metal convective heat transfer: a review. Appl. Therm. Eng. 193, 117021 (2021).

Yao, S. et al. Efficient roller-driven elastocaloric refrigerator. Nat. Commun. 15, 7203 (2024).

Michaelis, N., Schütze, A., Welsch, F., Kirsch, S.-M. & Seelecke, S. Novel experimental approach to determine elastocaloric latent heat. Shap. Mem. Superelasticity 5, 352–361 (2019).

Kirsch, S.-M. et al. NiTi-based elastocaloric cooling on the macroscale: from basic concepts to realization. Energy Technol. 6, 1567 (2018).

Louia, F., Michaelis, N., Schütze, A., Seelecke, S. & Motzki, P. A unified approach to thermo-mechano-caloric-characterization of elastocaloric materials. J. Phys. Energy 5, 045014 (2023).

Zhang, J., Zhu, Y., Cheng, S., Yao, S. & Sun, Q. Effect of inactive section on cooling performance of compressive elastocaloric refrigeration prototype. Appl. Energy 351, 121839 (2023).

Zhang, K., Kang, G. & Sun, Q. High fatigue life and cooling efficiency of NiTi shape memory alloy under cyclic compression. Scr. Mater. 159, 62–67 (2019).

Qian, S., Yuan, L., Yu, J. & Yan, G. et al. Numerical modeling of an active elastocaloric regenerator refrigerator with phase transformation kinetics and the matching principle for materials selection. Energy 141, 744–756 (2017).

Yuan, L., Liu, Y., Yu, J. & Qian, S. Experimental study on cooling performance of active magnetic regenerators with different structures. Int. J. Refrig. 153, 184–193 (2023).

Zhang, J., Zhu, Y., Yao, S. & Sun, Q. Highly efficient grooved NiTi tube refrigerants for compressive elastocaloric cooling. Appl. Therm. Eng. 228, 120439 (2023).

Liang, D. et al. Ultrahigh cycle fatigue of nanocrystalline NiTi tubes for elastocaloric cooling. Appl. Mater. Today 26, 101377 (2022).

Xiao, F., Bucsek, A., Jin, X., Porta, M. & Planes, A. Giant elastic response and ultra-stable elastocaloric effect in tweed textured Fe-Pd single crystals. Acta Mater. 223, 117486 (2022).

Wang, H. et al. Giant elastocaloric effect and improved cyclic stability in a directionally solidified (Ni50Mn31Ti19)99B1 alloy. Materials 17, 4756 (2024).

Dang, P. et al. Low-fatigue and large room-temperature elastocaloric effect in a bulk Ti49.2Ni40.8Cu10 alloy. Acta Mater. 229, 117802 (2022).

EngineersIreland. The L12 heat pump by Exergyn. https://www.youtube.com/watch?v=pklqEtP5k-c (YouTube, 2021).

Unmüßig, S., Burghardt, A., Schäfer-Welsen, O. & Bartholomé, K. Highly efficient drive system for elastocaloric heat pumps and cooling systems. Shap. Mem. Superelasticity 10, 177–188 (2024).

Zhang, J., Cheng, S. & Sun, Q. Roller-cam-driven compressive elastocaloric device with high cooling power density. Device https://doi.org/10.1016/j.device.2024.100677 (2025).