Yao, Y. et al. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science 359, 1489–1494 (2018).

Li, M. et al. High-entropy alloy electrocatalysts go to (sub-) nanoscale. Sci. Adv. 10, eadn2877 (2024).

Gao, S. et al. Synthesis of high-entropy alloy nanoparticles on supports by the fast moving bed pyrolysis. Nat. Commun. 11, 2016 (2020).

Wang, B. et al. General synthesis of high-entropy alloy and ceramic nanoparticles in nanoseconds. Nat. Synth. 1, 138–146 (2022).

Chen, P.-C. et al. Polyelemental nanoparticle libraries. Science 352, 1565–1569 (2016).

Sun, Y. & Dai, S. High-entropy materials for catalysis: a new frontier. Sci. Adv. 7, eabg1600 (2021).

Yao, Y. et al. High-entropy nanoparticles: synthesis-structure-property relationships and data-driven discovery. Science 376, eabn3103 (2022).

Xin, Y. et al. High-entropy alloys as a platform for catalysis: progress, challenges, and opportunities. ACS Catal. 10, 11280–11306 (2020).

Liu, Y.-H. et al. Toward controllable and predictable synthesis of high-entropy alloy nanocrystals. Sci. Adv. 9, eadf9931 (2023).

Ouyang, B. & Zeng, Y. The rise of high-entropy battery materials. Nat. Commun. 15, 973 (2024).

Liu, D. et al. Exceptional fracture toughness of CrCoNi-based medium-and high-entropy alloys at 20 kelvin. Science 378, 978–983 (2022).

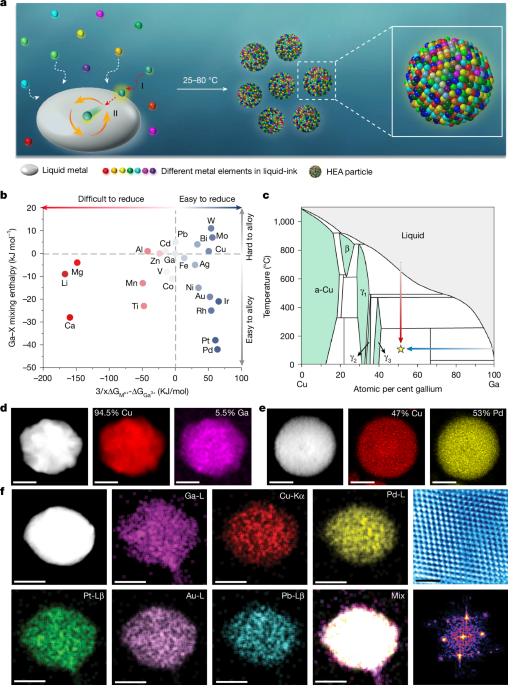

Cao, G. et al. Liquid metal for high-entropy alloy nanoparticles synthesis. Nature 619, 73–77 (2023).

Kang, Y. et al. Mesoporous multimetallic nanospheres with exposed highly entropic alloy sites. Nat. Commun. 14, 4182 (2023).

Zhan, C. et al. Subnanometer high-entropy alloy nanowires enable remarkable hydrogen oxidation catalysis. Nat. Commun. 12, 6261 (2021).

Li, Y. et al. Cu-based high-entropy two-dimensional oxide as stable and active photothermal catalyst. Nat. Commun. 14, 3171 (2023).

Zavabeti, A. et al. A liquid metal reaction environment for the room-temperature synthesis of atomically thin metal oxides. Science 358, 332–335 (2017).

Idrus-Saidi, S. A. et al. Liquid metal synthesis solvents for metallic crystals. Science 378, 1118–1124 (2022).

Taccardi, N. et al. Gallium-rich Pd–Ga phases as supported liquid metal catalysts. Nat. Chem. 9, 862–867 (2017).

Hong, S.-J. & Suryanarayana, C. Mechanism of low-temperature θ-CuGa2 phase formation in Cu-Ga alloys by mechanical alloying. J. Appl. Phys. 96, 6120–6126 (2004).

Brandes, E. A. & Brook, G. Smithells Metals Reference Book (Elsevier, 2013).

Dean, J. A. Lange’s Handbook of Chemistry (McGraw-Hill, Inc., 1999).

Yao, Y. et al. Computationally aided, entropy-driven synthesis of highly efficient and durable multi-elemental alloy catalysts. Sci. Adv. 6, eaaz0510 (2020).

Chang, X., Zeng, M., Liu, K. & Fu, L. Phase engineering of high‐entropy alloys. Adv. Mater. 32, 1907226 (2020).

Young, D. A. Phase Diagrams of the Elements (Univ. California Press, 2023).

Gan, T., Handschuh-Wang, S., Shang, W. & Zhou, X. GaOOH crystallite growth on liquid metal microdroplets in water: influence of the local environment. Langmuir 38, 14475–14484 (2022).

Turnbull, D. Kinetics of solidification of supercooled liquid mercury droplets. J. Chem. Phys. 20, 411–424 (1952).

Kalikmanov, V. I. Nucleation Theory (Springer, 2013).

Takeuchi, A. & Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 46, 2817–2829 (2005).

Tandoc, C., Hu, Y.-J., Qi, L. & Liaw, P. K. Mining of lattice distortion, strength, and intrinsic ductility of refractory high entropy alloys. npj Comput. Mater. 9, 53 (2023).

Khalajzadeh, V. & Beckermann, C. Simulation of shrinkage porosity formation during alloy solidification. Metall. Mater. Trans. A 51, 2239–2254 (2020).

Gránásy, L., Pusztai, T., Börzsönyi, T., Warren, J. A. & Douglas, J. F. A general mechanism of polycrystalline growth. Nat. Mater. 3, 645–650 (2004).

Yamaguchi, A., Mashima, Y. & Iyoda, T. Reversible size control of liquid‐metal nanoparticles under ultrasonication. Angew. Chem. Int. Ed. 54, 12809–12813 (2015).

Yu, Q. et al. Identifying surface structural changes in a newly-developed Ga-based alloy with melting temperature below 10 °C. Appl. Surf. Sci. 492, 143–149 (2019).