Materials

Caesium iodide (CsI, 99.99%), molybdenum trioxide (MoO3), silicon dioxide (SiO2) and titanium dioxide (TiO2) were purchased from Sigma Aldrich. Polyethylenimine (average molecular weight 50,000, 37% solution in H2O) was purchased from J&K Scientific. Lead iodide (PbI2, 99.99%), formamidinium bromide (FABr, 99.99%) and formamidinium iodide (FAI, 99.99%) were purchased from TCI. Sulfonamide (SFA) was purchased from Macklin Biochemical. Poly(9,9-dioctylfluorene-co–N-(4-butylphenyl)-diphenylamine) (TFB) and zinc oxide (ZnO) nanocrystals (10% wt in H2O) were purchased from Xian Yuri Solar. Dimethyl sulfoxide (DMSO), gamma-butyrolactone (GBL), ethyl acetate, ethanol, isopropanol alcohol, N,N-dimethylformamide (DMF) and chlorobenzene (CB) were purchased from Aladdin. Gold pellets were purchased from Hebei Jiuyue New Material Technology. All chemicals were used as received without further purification.

Preparation of perovskite precursor solution

The Cs0.5FA0.5PbI2Br precursor solution was prepared by dissolving CsI, PbI2, FABr and SFA in DMF with a molar ratio of 0.5:1:0.5:0.06. The concentration of Pb2+ in the precursor solution was 0.11 mol l−1. For single-crystal growth, FAI and PbI2 in different molar ratios were fully dissolved in a mixed solvent of GBL/DMSO (volume ratio 4:1) to obtain a 1.2 M perovskite precursor solution. The precursor solution was stirred at room temperature in an N2-filled glovebox for about 2 h. The solution was filtered with polytetrafluoroethylene filters (0.22 μm) before use.

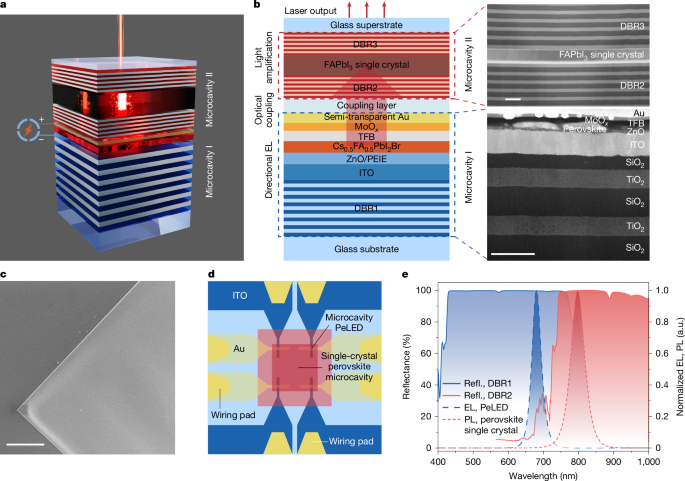

Fabrication of DBRs

Alternating layers of silicon dioxide (SiO2, n = 1.478) and titanium nitride (TiO2, n = 2.498) were deposited onto glass substrates to form DBRs, using an e-beam evaporator with its chamber enclosed in a nitrogen glovebox. DBR1 in microcavity I was targeted for high reflectance in the 450–750 nm wavelength range, so that the emission at about 680 nm could be reflected and directed towards the semi-transparent Au electrode. DBR1 consists of approximately 30 pairs of SiO2/TiO2, with the thicknesses controlled to be 115 nm and 68 nm for each pair of SiO2 and TiO2 layers, respectively. DBR2 in microcavity II showed high reflectance (>98%) at 750–1,000 nm and high transmittance (>90%) below 680 nm. To fabricate DBR2, about 20 pairs of SiO2/TiO2 were deposited, with thicknesses controlled to be 142 nm and 85 nm for each pair of SiO2 and TiO2 layers, respectively. DBR3 in microcavity II may share the same design as DBR2 in unoptimized devices. In optimized devices, DBR3 is redesigned to feature high reflectance (>98%) at 620–870 nm. To fabricate the optimized DBR3, about 20 pairs of SiO2/TiO2 were deposited, with thicknesses controlled to be 125 nm and 75 nm for each pair of SiO2 and TiO2 layers, respectively.

Fabrication of the single-crystal perovskite microcavity

Gold stripes (thickness about 0.2 μm) were evaporated onto the two edges of the DBR as a spacer. A pair of DBR and glass was pressed against each other and bonded together by a clip to form empty channels. A drop of FAPbI3 perovskite precursor solution (5 μl) was then injected from the edge of the DBR/glass pair, penetrating the channels because of capillary force. The growth of the FAPbI3 perovskite single crystals was completed in an N2-filled glovebox. The annealing temperature for the samples was gradually increased from 60 °C to 130 °C at a rate of 2 °C min−1, then kept at 130 °C for 12 h. Finally, the temperature of the samples was gradually cooled down to room temperature. The total duration of the crystal growth was about 2 days. The glass substrate was removed using a thin razor blade. The FAPbI3 single crystal on DBR was then transferred into an e-beam evaporator for depositing another DBR on top of the single crystal, completing the fabrication of microcavity II. The optimum thickness of the FAPbI3 single crystals was found to be about 180 nm.

Fabrication of the integrated dual-cavity perovskite lasers

The DBR/glass substrates were sequentially cleaned using deionized water, acetone and isopropanol under ultrasonication. The substrates were dried with a nitrogen blowgun and exposed to UV–ozone for 15 min before use. ZnO nanoparticles were subjected to spin-coating onto the DBR substrates at 5,000 rpm for 45 s and then annealed at 150 °C for 10 min. Subsequently, a PEIE solution (0.04 wt% in isopropanol) was subjected to spin-coating on top of the ZnO layer at 5,000 rpm for 45 s, followed by annealing at 100 °C for 10 min. After cooling down to the ambient temperature, the samples were transferred into an N2-filled glovebox. The perovskite precursor solution was subjected to spin-coating onto the PEIE-coated ZnO substrates at 5,000 rpm for 60 s, followed by annealing at 100 °C for 10 min. Next, a TFB solution (12 mg ml−1 in chlorobenzene) was subjected to spin-coating at 4,000 rpm for 45 s. Subsequently, 7 nm of MoOx and 20 nm of Au were sequentially evaporated through a shadow mask under a high vacuum to form the semi-transparent electrode. The top surface of the resultant microcavity PeLED (microcavity I) was covered by UV epoxy (NOA 81). Following this step, microcavity II containing the FAPbI3 single crystal was placed on top of microcavity I, with the single crystal positioned on top of the overlapping area of ITO and Au. The device was then exposed to UV light for 30 s to form a reliable bond between the two microcavities, completing the integration process.

Surface morphology measurements for perovskite single crystals

The surface morphology of the perovskite single crystals was inspected using a field emission scanning electron microscope (Hitachi, SU70 SEM). The surface roughness of the samples was characterized using an atomic force microscope (Bruker, Multimode-8) under the tapping mode. The thickness of perovskite single crystals was measured using a stylus profilometer (Bruker, DektakXT).

Scanning transmission electron microscopy experiments

A spherical aberration-corrected scanning transmission electron microscope (FEI, Titan ChemiSTEM) was used for collecting the cross-sectional images of the integrated dual-cavity laser devices. The samples for HAADF-STEM measurements were prepared using a dual-beam focused-ion-beam system (Quata 3D FEG).

XRD measurements

The standard XRD measurements of the samples were performed using Shimadzu XRD 7000 with Cu Kα1,2 radiation (λ = 1.541 Å). The measurements were performed at a continuous mode with a scan range of 10° < 2θ < 60° and a scan speed of 5° min−1. The 2D diffraction images were collected using a single-crystal X-ray diffractometer with a 2D detector (D8 Venture, Bruker). The powders scratched from the single crystals were placed on a quartz substrate. The monochromatic X-ray beam was focused onto the powders. The Bragg reflections were detected using a MAR-165 charge-coupled device detector with an exposure time of 60 s.

Photoluminescence and optical reflection measurements

A 405-nm continuous wave laser was used to excite the FAPbI3 single crystals and the Cs0.5FA0.5PbI2Br polycrystalline films. The photoluminescence spectra were obtained by a high-sensitivity spectrometer (QE-Pro, Ocean Optics). The reflectance of the DBRs was measured by a custom-built setup. The white light from a halogen lamp was incident normally on the DBRs through one of the ports on a Y-type fibre. The reflected light was collected through another port on the Y-type fibre and directed into a spectrometer (USB 4000, Ocean Optics). An aluminium mirror was used as the reference sample for optical reflection.

Characterization of microcavity PeLEDs under d.c. and pulsed operations

For d.c. operation, the microcavity PeLEDs were driven by a computer-controlled source meter (Keithley 2450). The voltage was swept from 1 V to 7 V at a rate of 0.2 V per step. Simultaneously, the EL emitted from the microcavity PeLED through the semi-transparent Au electrode was measured using a calibrated photodetector (819D-SL-2-CAL, Newport) in an integrating sphere, with a silicon photodiode used in conjunction with a computer-controlled optical power meter (Newport 1936-R). The EL spectra of the PeLEDs were measured using a fibre-coupled spectrometer (QE-Pro, Ocean Optics) on another port of the integration sphere. The EQE was obtained by dividing the total number of emitted photons by the total number of injected electrons per unit time. The measurements were performed in the dark under ambient conditions.

For pulsed operation, a pulse generator (AVTECH 1010-B) was used to provide voltage pulses (pulse width 1 μs, repetition rate 100 Hz) with a d.c. offset bias of 1.7 V. The emitted optical power from the devices was measured using a silicon photodiode (FDS1010, Thorlabs). The photodiode was connected to a custom-built large-bandwidth transimpedance amplifier. The amplified signal was then sent to an oscilloscope (MDO34, Tektronix) to obtain the average optical power output based on the responsivity of the photodiode. To measure the transient profiles, the PeLED was connected in series with a 2-ohm resistor. The transient voltage signal on the resistor was amplified by a voltage amplifier (FEMTO DHPVA-101) and collected by the oscilloscope. The transient current signal was obtained by dividing the voltage by the resistance.

Characterization of angular emission profiles of PeLEDs

To measure the angular emission profiles, the PeLED was positioned at the centre of a rotational stage, with a fibre-coupled spectrometer (QE-Pro, Ocean Optics) placed at a fixed distance. The EL spectra at different angles were measured while rotating the stage.

Optically pumped lasing experiments

Microcavity II was pumped by 1-µs optical pulses from a modulated 405-nm continuous wave laser at a repetition rate of 10 Hz. The continuous wave laser was synchronized with an arbitrary-wave generator, which produced square waves with an amplitude of 5 V. The excitation beam was directed through a tunable neutral density filter (Thorlabs, NDC-50C-2M-B) to adjust the excitation intensity. A small fraction of the beam was directed onto a photodiode (Thorlabs, DET110) for pump power monitoring. The rest of the beam was directed into an inverted microscope and then focused onto the sample through a 50× objective, producing a spot size of around 18 μm. The output emission from the laser was measured using a fibre-coupled spectrometer (Maya 2000, Ocean Optics) with a spectral resolution of 0.08 nm. The measurements were performed under ambient conditions (temperature about 22 °C; relative humidity about 50%). For the femtosecond laser-pumped lasing, the optical excitation (400 nm; pulse duration around 270 fs; repetition rate 50 kHz) was generated using an optical parametric amplifier (Orpheus-F, Light Conversion) pumped by a 1,030 nm Yb:KGW laser (Pharos, Light Conversion).

Characterization of electrically driven lasing

The dual-cavity perovskite device was driven by a pulse generator (AVTECH 1010-B). The output emission from the dual-cavity laser was measured using a high-resolution fibre-coupled spectrometer (Maya 2000, Ocean Optics). Different current densities were obtained by adjusting the amplitude of the voltage pulses. The far-field emission beams were captured using a high-resolution beam profiler CCD camera (Thorlabs, BC207VIS). The polarization properties of the emission were characterized based on the emission intensities measured through a rotatable linear-polarizer plate. For the stability measurements, the laser device was driven by voltage pulses (peak current density 163 A cm−2, pulse duration: 1 μs and repetition rate 10 Hz), with the output emission continuously measured using a fibre-coupled spectrometer (Maya 2000, Ocean Optics) with a spectral resolution of 0.08 nm. The measurements were performed under ambient conditions (temperature about 22 °C; relative humidity around 50%).

Simulation of optical power distribution

The optical simulation was carried out using the commercial software LightTools. The optical power (irradiance) distribution at the plane of the perovskite single crystal (in microcavity II) was simulated for both single-cavity bottom-emission and dual-cavity top-emission devices. During the simulation, 2D receivers were placed at the plane of the PeLED active area (serving as the excitation source) and the perovskite single crystal within microcavity II. The PeLED active area was regarded as an assembly of numerous point-light sources and was partitioned into 1 μm × 1 μm sections. The output irradiance was normalized to a value of 100. For each point source, either a Lambertian profile or a microcavity angular profile was assigned as the angular emission profile. The optical power reaching the 2D receiver at the plane of the single-crystal layer was computed. Subsequently, all the fractional optical power was integrated for each position to obtain the overall distribution.

Frequency-response measurements

The dual-cavity laser device was driven by a square-wave voltage signal with various frequencies, supplied by an arbitrary-wave generator. The output emission from the device was directed to a fibre-coupled avalanche photodetector (Thorlabs, APD430A2/M). The signal was fed into an oscilloscope (MDO34, Tektronix). The amplitudes of the signals were recorded at different frequencies. The 3 dB frequency or the bandwidth corresponding to the frequency at which the amplitude drops to half of its original value. The frequency-response characteristics of the integrated laser were measured similarly, but driven by a low duty-cycle (10%) pulse train.