With the current state of automotive manufacturing relying on components traveling across oceans before final assembly, it’s easy to forget there was a time when it was more profitable for automakers to operate a single massive factory. No other place better exemplifies the monumental scale required for vertically integrated mass production than the Ford River Rouge Complex. The facility that opened as the world’s largest factory by 1928 resulted from Henry Ford’s obsession with making his company self-sufficient and could convert raw materials into completed automobiles ready for the showroom.

The 2,000-acre site along the River Rouge was purchased by the weed-eating industrialist in 1915, according to the Henry Ford. He didn’t initially envision the site as a place for production, but as a bird sanctuary. However, those plans were derailed by World War I. The U.S. Navy tasked Ford with constructing Eagle Boats, surface vessels designed to hunt Imperial German U-boats. As a result, the manufacturer dredged maritime access to the Detroit River for the site, which quickly became crucial for operations.

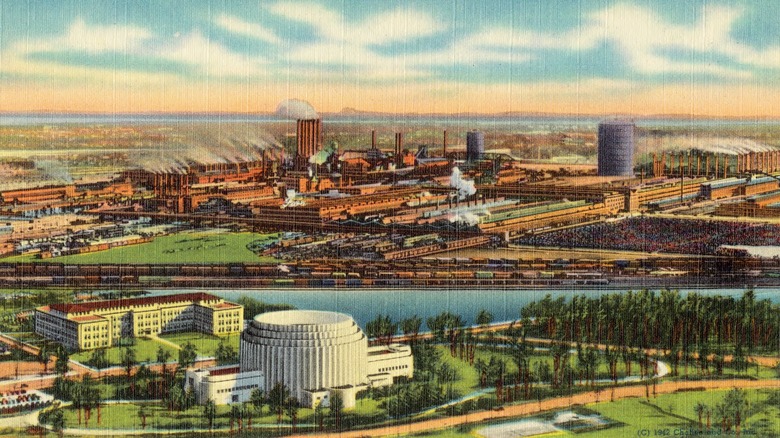

The Fordson tractor became the first land vehicle mass-produced at River Rouge in 1917. During the production run, the complex would expand to cover demands beyond mere assembly. Ford constructed an onsite steel mill and foundry with the necessary ore shipped in on lake freighters. By the time traction production was entirely moved to Ireland in the late 1920s, River Rouge produced every component for the Model T. However, those components were still being shipped to Ford’s Highland Park factory for final assembly. The Model A would be the first vehicle entirely built at the complex in 1927.

A century-old factory ready for the next century

The final assembly of Model A happened in Building B, the same building where the Eagle Boats were built. However, the factory complex sprawled out from around the three-story structure. A company diagram of the site during the 1930s shows a motor assembly plant, a glass works, a paper mill and a power plant. To shuttle material and components between different portions of River Rouge, Ford operated a 100-mile railroad that didn’t leave the site’s confines. River Rouge had a combined floor area of 15.7 million square feet at its peak, nearly four times the size of Boeing’s Everett Factory in Washington.

It would be a disservice to discuss River Rouge without mentioning the United Auto Workers. The Battle of the Overpass, a pivotal moment in American history, took place at the factory complex in May 1937. The Ford Service Department, the automaker’s private security force, brutally attacked UAW organizers outside River Rouge’s main gates by the aforementioned overpass. The circulated photos of the assault shifted the general public’s perception of Ford and would even lead to the company going to the negotiating table. Ford was the final holdout among the Big Three in recognizing the UAW.

The UAW played a significant role in keeping River Rouge open despite the seismic shifts in how cars are produced today. Ford has sold off sizable portions of the complex during the 1980s, including its waterfront and steel mill. By the early 1990s, the Fox body Mustang was reaching the end of its production run, and its demise would have likely led to River Rouge’s closure as the only vehicle built there. Ford was pushed to develop a fourth-generation Mustang and modernize the complex by the UAW. River Rouge’s future is seemingly secure as the F-150 and F-150 Lightning are built there today, and I don’t think pickup truck sales will end anytime soon.