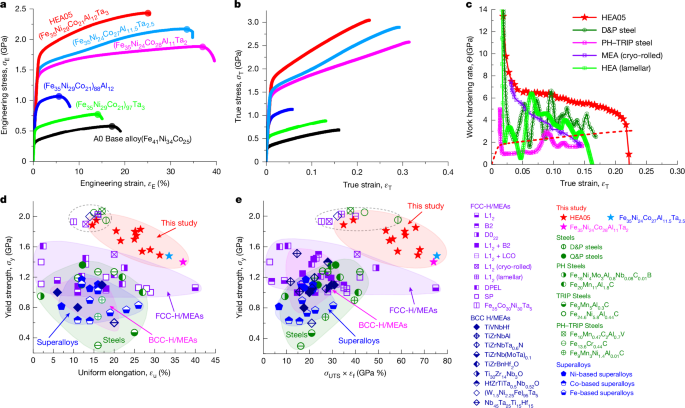

The highly heterogeneous microstructure consisting of dual precipitates in the FCC concentrated solid solution (‘matrix’) endows the HEA05 Fe35Ni29Co21Al12Ta3 alloys with extraordinary mechanical properties, as shown in Fig. 3a,b. For comparison, we started from single-element alloying, which increased the strength σy from approximately 300 MPa for the A0 base alloy to approximately 500 MPa for 3 at.% Ta and to approximately 800 MPa for 12 at.% Al. Nevertheless, the latter two alloys exhibited notably reduced ductility, particularly εu. By contrast, both εu (25%) and εf of the (750 °C for 1 h) HEA05 alloy were far superior, simultaneously with a drastically elevated σy (1.75 GPa) 6-fold over the A0 base alloy. Yet, it showed an even higher WHR at the same time, enabling a notably enhanced tensile elongation (Fig. 3a and Extended Data Fig. 7). To further testify the superiority of HEA05, another two FeNiCoAlTa alloys were prepared with somewhat reduced Al and Ta concentrations, that is, Fe35Ni24Co28Al11Ta2 and Fe35Ni24Co27Al11.5Ta2.5 alloys, containing less B2 volume fractions at approximately 8% and 11%, respectively (Fig. 3 and Supplementary Fig. 8). They have lower σy but larger εu. Notably, we tuned the processing condition of our HEA05 alloy at its fixed composition and observed a range of tensile stress–strain curves (compiled in Extended Data Fig. 7), all showing significant strain hardening and large εu at high σy between 1.5 and 1.95 GPa. As summarized in Fig. 3d,e), the systematic data (elliptical area covering the data points represented by red stars) demonstrate the tunability and trend of performance, ranging from 1.5 GPa (31%) to 1.95 GPa (15%). Taken as a group, the entire ellipse presented strength–ductility combinations superior to all previous alloys.

a, Engineering stress–strain curve. b, True stress–strain curve of the HEA05 alloy (750 °C for 1 h) compared with its base alloy A0 (Fe41Ni34Co25), with (Fe35Ni29Co21)88Al12, (Fe35Ni29Co21)97Ta3, Fe35Ni24Co27Al11.5Ta2.5 (light blue) and Fe35Ni24Co28Al11Ta2 (pink). c, Comparison of WHRs Θ with some 2-GPa steels2,3 and 2-GPa HMEAs19,20. (The alloys inside the light purple colours in d and e have serrated WHR curves.) d, Comparison with representatives of other high-strength alloy categories in yield strength and uniform elongation space. Our new alloys in the oval area (for the tensile curves of HEA05 processed under different conditions, see Extended Data Fig. 7 and Extended Data Table 1) clearly stood out, outperforming all previous alloys. e, Strength σy versus the product of σUTS and εf of HEA05 alloys, showing that the latter also outranked other ultra-high-strength FCC HEAs strengthened by L12 (refs. 18,27,28,42,50); B2 (refs. 15,21,30); D022 (ref. 34); L12 and B2 (refs. 14,16,31,32,33); L12 and LCO4; cryo-rolled HEAs19; lamellar HEAs20; DPEL29,35; single phase (SP)5,36,37,38; BCC-M/HEAs39,40,41; Fe-based, Co-based and Ni-based superalloys12; D&P steels2; quenched and partitioned (Q&P) steels11,43; precipitation hardened (PH) steels25; TRIP steels25; and PH–TRIP steels25.

This oval-shaped new territory is centred around the impressive point reported in Fig. 3a, which shows a σy = 1,750 ± 50 MPa, σUTS = 2,403 ± 46 MPa, stable WHR Θ higher than 2 GPa across the entire strain range and εu = 25 ± 1.5%. This combination stood out when compared with the best of bulk steels1,2,3,10,25 (Fig. 3c–e). The simultaneous ultra-high σy and large ɛu also set this HEA05 alloy apart (comparisons in Fig. 3d) from all previously reported precipitation-strengthened HEAs15,16,18,26,27,28,29,30,31,32,33,34, dual-phase eutectic lamellae (DPEL) HEAs16,29,35,36, single-phase HEAs5,36,37,38 and the best-performing BCC-HMEAs39,40,41, which have either lower strength or lower ductility (or both lower).

Figure 3b shows the tensile true stress–strain curves, showing that the HEA05 alloy can reach true stress as high as approximately 3 GPa. This is because of its superior WHR, clearly above the base A0, (Fe35Ni29Co21)88Al12 and (Fe35Ni29Co21)97Ta3 alloys. The work hardening capability, in terms of the strength difference σUTS − σy = 650 MPa or the yield ratio σy/σUTS = 0.73, is extraordinary. Finally, the HEA05 alloys (red stars) also have a high value of the product σUTS × εf (for example, 60 GPa %), outranking other high-performance alloys (Fig. 3e; the way to go is in the direction pointing towards the upper-right corner), including precipitation-strengthened L12 (refs. 18,27,28,42), B2 (refs. 15,21,30), D022 (ref. 34), L12 and B2 (refs. 14,16,31,32,33), L12 and LCO4. Their performance also surpassed that of cryo-rolled HEAs19; lamellar HEAs20; DPEL29,35; single phase5,36,37,38; Fe-based, Co-based and Ni-based superalloys12; D&P steels2; quenched and partitioned steels11,43; precipitation hardened steels25; transformation-induced plasticity (TRIP) steels25; and precipitation hardened–transformation-induced plasticity (PH–TRIP) steels25.

Note that to avoid violating the Considère instability criterion to maintain uniform tensile elongation, the WHR must always remain higher than the flow stress in the tensile test. In Fig. 3c, the previous approximately 2-GPa HEAs and steels that came close to HEA05 in WHR all exhibited stress serrations and plunges in the WHR curve to below the true stress–strain curve of HEA05, as seen superimposed using a dashed curve. Thus, these alloys suffer from unstable plastic flow and hence are placed in the dashed circle in Fig. 3d,e. In other words, they would succumb to strain localization at some point soon after yielding, and HEA05 is the only alloy with consistently stable WHRs Θ higher than 2 GPa across a wide strain range. Similarly, a high WHR was observed for HEA05 processed under other conditions (Extended Data Fig. 7c). Notably, the impressive Θ and εu ensured high processibility in shaping/forming and a large safety margin against fracture for our high-strength alloys, which is highly desirable for engineering applications.

In what follows, we illustrate the underlying mechanisms for the high strength and extraordinary work hardening capability. Coherent strengthening by the L12-type precipitates has been extensively investigated in Ni-based superalloys and HMEAs. The HEA05 combines, in one alloy, the following three desirable attributes: (1) the coherent L12 nanoprecipitates are effectively strengthened using Ta alloying, and their volume fraction is close to the highest ever for superalloys (such as René N5); (2) with our significant Al addition, the B2 phase fraction is also rather high among the reported HEAs; and (3) the MCIPs in our alloys contain a high level of extra elements and are, therefore, far more ductile and strain-hardenable than traditional intermetallic compounds44,45 (further discussion later).

First, we discuss the ultra-high yield strength. This results from the densely populated L12 nano-MCIPs and B2 micro-MCIPs in an effectively solid solution-strengthened FCC matrix (Supplementary Fig. 9 and Supplementary Note 4). The volume fraction of precipitates in our alloy was extraordinarily high for both L12 (approximately 67%) and B2 (approximately 15%). The precipitate hardening in the coherent FCC/L12 case is mainly attributable to the γAPB cost for the step creation by the interface-crossing dislocation, particularly for the Ta-alloyed L12 nano-MCIPs that have a higher γAPB than the base L12 and Ti-alloyed ones (Extended Data Fig. 1). In the FCC/B2 case, the incoherent interfaces are strong traps for glide dislocations and thus are effective barriers for slip transmission. As expected, the calculation of yield strength (Supplementary Note 5) revealed that coherent L12 nano-MCIPs dominated the σy enhancement (approximately 859 MPa), followed by incoherent B2 micro-MCIPs (approximately 351 MPa), lattice friction (approximately 277 MPa), stored dislocations (approximately 206 MPa) and grain boundaries (approximately 167 MPa).

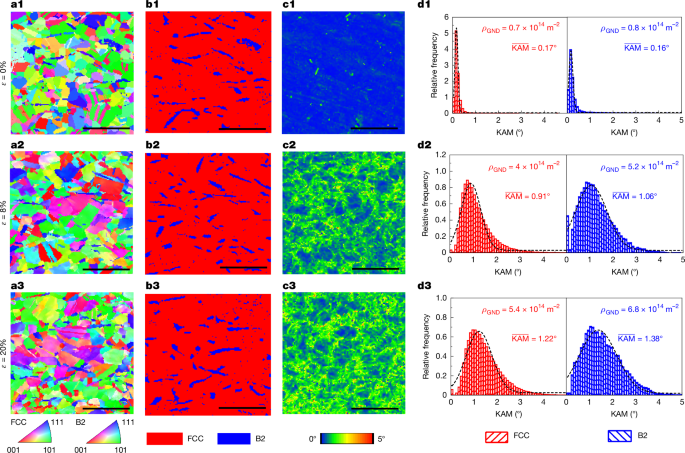

Next, we explain the extraordinary work hardening that sustains the large εu upon uniaxial tensile loading, as shown in Fig. 3. The dislocation densities of HEA05 at different deformation stages were monitored using a transmission electron microscope (TEM) (Fig. 2a,b and Extended Data Fig. 8), transmission Kikuchi diffraction (TKD; Extended Data Fig. 9) and electron backscatter diffraction (EBSD; Fig. 4). After 5% strain, the L12 nano-MCIPs were sheared by gliding dislocations, as shown in Fig. 2. (Some were observed at the FCC/L12 and FCC/B2 interfaces). Figure 4c(1–3),d(1–3) shows that as the strain increased from 8% to 20%, the kernel average misorientation (KAM) value of L12 in the FCC regions increased slightly from 0.91° to 1.22°, whereas that of B2-MCIPs increased from 1.06° to 1.38°. This indicates that the geometrically necessary dislocation (GND, ρGND) density increased with increasing plastic strains (Supplementary Note 6). The GND density ratio of the L12-dominant FCC to the B2 phase monotonically decreased from 0.87 at 0% strain to 0.79 at 20% strain (Fig. 4d(1–3)). The TKD results also revealed that both phases contained abundant GNDs with KAM less than 2° (Extended Data Fig. 9). TEM also revealed abundant dislocations accumulated inside B2-MICPs (Extended Data Fig. 8), indicating their heavy involvement in co-deformation. This is different from the traditional hard B2 phase, which often shows brittle fracture at low strain levels10. The high ρGND accumulated in B2 during tensile straining (note that in Fig. 4d(3), ρGND in B2-MCIPs is higher than that in the L12 + FCC; Extended Data Figs. 8 and 9) led to strain hardening along with tensile straining. This emphasizes that these B2-MCIPs are not only shearable by dislocations but also amenable to dislocation multiplication inside. This striking ductile behaviour of B2 can be attributed to its significantly depressed chemical ordering energy (Extended Data Fig. 1) and reduction in dislocation strain energy (caused by the FCC–B2 modulus mismatch when the dislocations transmitted across their incoherent interfaces46,47; Supplementary Note 2). Although the binary NiAl B2 phase has a high γAPB of approximately 671 mJ m−2, alloying (particularly with Ta) into B2 reduces this γAPB by approximately 30% (ref. 48), rendering the intermetallic deformable through dislocations and yet still strong. Meanwhile, the strength differences between the L12, B2 and FCC matrices would promote non-homogeneous deformation, adding GNDs that enhance WHRs. This mechanism has recently been recast as hetero-deformation-induced (HDI) hardening (Supplementary Fig. 10)49. The unusually heterogeneous microstructure in our complex alloy, with hierarchical inhomogeneities including interfaces on ultrafine to nanometre scales, would give rise to extra strain hardening39. Given our extraordinarily high densities of precipitates, dislocation trapping/tangling, reactions and multiplication are expected to be more effective than those in previous alloys. Furthermore, the interphase interfaces serve as sustainable dislocation sources at high stress.

In conclusion, we developed a high-entropy alloy (Fe35Ni29Co21Al12Ta3), assisted by domain knowledge-guided machine learning. The new alloy has a highly heterogeneous microstructure that comprises unusually dense MCIPs in an HEA FCC matrix, including both coherent L12 nanoprecipitates and incoherent lower-modulus-yet-hard B2 particles, which not only effectively impart strengthening, but also profusely interact with dislocations to sustain a high WHR above 2 GPa to large true strains. The appreciable volume fraction of the ductile B2-MCIPs with effective dislocation accumulation adds room for strain hardening. Our HEAs, with a yield strength of 2 GPa, rival super steels and yet have excellent uniform ductility towards the level of elemental metals, thus go beyond what the best bulk steels have to offer. Our alloy design strategy, through active learning-guided heavy alloying and extraordinary amounts of precipitates, including ductile (and work-hardenable) second phase, is expected to be applicable to other alloy systems. This pushes the envelope of mechanical properties (towards the upper-right corner of the strength–ductility space) and expands the material selection repertoire for demanding applications.