A worker checks on the production of low-carbon materials in Huaibei, eastern China.Credit: NurPhoto/Getty

Buying an ice cream in hot weather presents a challenge for those who prefer to linger over their summer snack: it can be a matter of seconds before even the hardiest product turns to soup. An experiment by a team of researchers in China provides some hope for those with such time-management issues. Their biodegradable ‘passive cooling’ wrapper — which works, in part, by radiating heat into space — kept an ice cream perfectly intact for 80 minutes after being placed in the sunshine1.

The experiment had an important motive. According to Jia Zhu, a materials-science researcher at Nanjing University who led the work, it showed that such materials have huge potential in a warming climate. When an 80 m2 sheet of the same material was laid on the surface of China’s Tianshan Glacier No. 1 in Xinjiang, the covered section was about 70 cm higher after 20 days. Other researchers have used similar materials on rooftops to cool buildings without consuming energy.

Nature Index 2024 Materials science

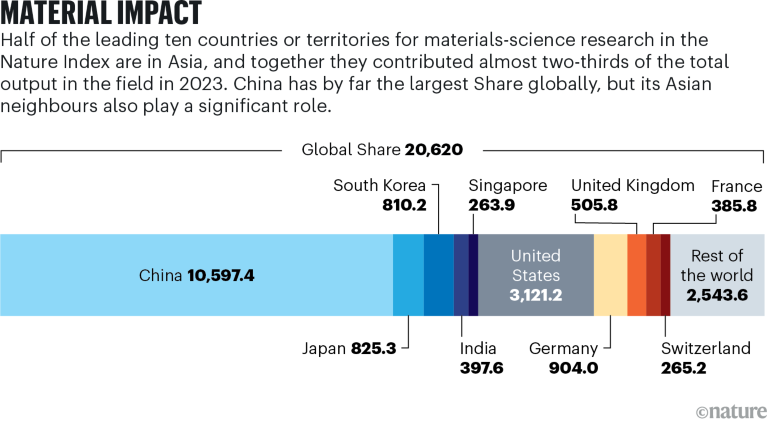

The hunt for passive-cooling solutions is one example of the surge in materials-based green-technology research under way across Asia, a focus that might be a factor behind Asian countries’ increasing dominance in materials science in the Nature Index. In 2023, China, Japan, South Korea, India and Singapore all made the global top 10 for materials-science output by country. Together, their combined Share (the metric that measures a country or institution’s output in Index journals) accounted for 63% of global output in the field.

Much of the green-materials work is dominated by research on next-generation batteries and solar cells, but numerous other technologies are under investigation, often with a focus on materials designed to interact with sunlight in unusual and potentially useful ways.

“In nature, light and heat are the two most powerful forms of energy,” Zhu says. “I explore ways to manipulate light and heat using hierarchically structured materials.” The ice-cream study showed hierarchical structure in action. At the microscale, pores in the plant-derived cellulose acetate film scatter and reflect incoming sunlight, bouncing solar heat away. At the nanoscale, the film’s atomic structure radiates heat within a band of infrared light known as the atmospheric transparent window. This heat is not reabsorbed by any atmospheric gases and is lost to space — using the Universe as a vast heat sink to keep objects on Earth cool.

By keeping objects cool without consuming energy, such radiative cooling materials could be key to combating rising urban heat, says materials scientist Xiaobo Yin, who develops passive-cooling materials at the University of Hong Kong. “Air conditioning moves heat from inside the house to the outside, while consuming energy which adds more heat to the environment,” Yin says. “Buildings or roads capable of radiative cooling are the only way we can expel the excess heat out of the Earth.”

Asia’s mega-cities are among the places where passive cooling will be most important, says Yin, who moved to Hong Kong from the United States in 2021. It is one reason why research into sustainable materials is a priority in many Asian countries. According to Zhu, it also helps that there is a consensus on the need for action to deal with climate change. “I don’t think people in China have any doubt that climate change is real,” he says.

Zhu, who spent almost a decade studying and working in the United States — at Stanford University in California and the University of California, Berkeley — before joining Nanjing University in 2013, also points to the existing evidence that environmental challenges can be met through technology. When he returned to China, for instance, atmospheric pollution in cities was rife. “It was very clear how industrialization was impacting the wider environment,” he says. But a range of government measures — including encouraging electric-vehicle uptake — have since made a difference, he says.

Bin Liu, director of the National University of Singapore’s Flagship Green Energy Programme.Credit: National University of Singapore

Green-energy materials research is also important for the economy of many East Asian countries, Zhu adds, given their “heavy emphasis on manufacturing”, an energy-intensive process that could be made cheaper and less carbon-intensive by transitioning to renewable energy. There is also great potential to export novel green-energy technologies.

“Materials-science research is well supported in countries like India and China because they have recognized the potential for fundamental research to promote their manufacturing industry,” says Tianyi Ma, a materials scientist at RMIT University in Melbourne, Australia.

Asian countries also typically do very well in terms of investing funding into the translational phase of research to better connect academic ideas with industry, Ma adds. “It’s a win–win situation because in return, industry partners offer more financial support for fundamental research.”

Rose-tinted research

Aside from materials that reject sunlight to provide cooling, another highly active area of research in Asia is to develop materials that capture and use sunlight for sustainability gains. Yin’s latest focus was to develop a semi-translucent material that captures green light from the Sun and re-emits it as red light. “We’re trying to tailor the solar spectrum for better crops,” Yin says. Plants rarely use the green light in sunlight for photosynthesis — hence, leaves appear green as this light is reflected — so turning the green part of the solar spectrum into red light converts it into a form that plants can use.

Source: Nature Index

By tuning the solar spectrum in this way2, the microphotonic film, which Yin first worked on with colleagues while in the United States, boosted the growth of lettuces by more than 20%. The same gains were seen for plants grown under lights. “For vertical farming or vegetable factories, the primary energy cost is lighting,” Yin says. “It’s an area where our work could contribute.”

The team is developing a version of the film for sustainable biomanufacturing3. “We also want to tailor the solar spectrum for the fast growth of microalgae,” Yin says. The idea is to use microalgae to turn carbon dioxide emissions into valuable products, because the microalgae absorb CO2 as they grow, becoming rich in proteins and oils that can be harvested. The team is first targeting niche, high-value superfood or cosmetics applications. “But the more we scale up, the lower production costs, and the broader the range of products we could consider,” Yin says.

Harnessing light to drive the conversion of CO2 into valuable products is also a hot topic in Singapore, where the government prioritizes sustainable-materials research, although for different reasons than the region’s major manufacturing economies.

“Singapore is very short of natural resources,” says Bin Liu, a materials-science researcher at the National University of Singapore, and director of the university’s Flagship Green Energy Programme. “If we can convert CO2 emissions into a large-scale green fuel, that will solve sustainability and also energy-import issues in Singapore,” she says. “The government’s five-year plan has prioritized this area, so the funding support is tremendous in materials.”

Liu’s own lab explores organic photocatalytic materials, which can absorb the energy in sunlight and use it to drive chemical reactions. The team has used these materials to extract the carbon atoms from CO2, and the hydrogen atoms from water molecules, before combining them to make hydrocarbons that can act as fuel sources, such as green methanol.

“Once the cost of green methanol is comparable with petrochemical methanol, the world will embrace this renewable energy,” Liu says. An analysis found that the major cost of green methanol came from harvesting hydrogen from water. “In response, we raised funds to build a national Centre for Hydrogen Innovation with a focus on how to reduce hydrogen cost,” she says. Funding was led by a S$15-million (US$11.1-million) endowment gift from the state-owned investment company, Temasek.

The government also nurtures collaboration with leading researchers from other countries. One such initiative is the Campus for Research Excellence and Technological Enterprise (CREATE) programme. “We invite researchers from very good foreign universities to come to Singapore to work with us, to co-develop our research areas and materials,” says Liu. The latest CREATE initiative, focused on decarbonization, was awarded S$90 million to bring researchers to from 11 overseas institutions, including the University of Cambridge, UK; the Technical University of Munich, Germany; Shanghai Jiao Tong University, China; and the University of California, Berkeley.

“Singapore is very special in that it concurrently collaborates with the East and the West, which is unusual with today’s geopolitics,” Liu says. “We can form collaborations with the best partners, to complement our own strengths.”

Long-term state investment with strong support for collaboration has also underpinned the growth in sustainable-materials research in Japan, says Kazunari Domen, who studies metal-based photocatalyst materials for green hydrogen production at the University of Tokyo and at Shinshu University in Matsumoto.

Real-world applications were far from Domen’s mind when he started researching water-splitting photocatalysts in the 1980s. “Initially, I just found it interesting. But since 2000, when the need to produce green hydrogen to reduce carbon dioxide emissions became clear, our government started to provide a continuous, relatively big, budget.”

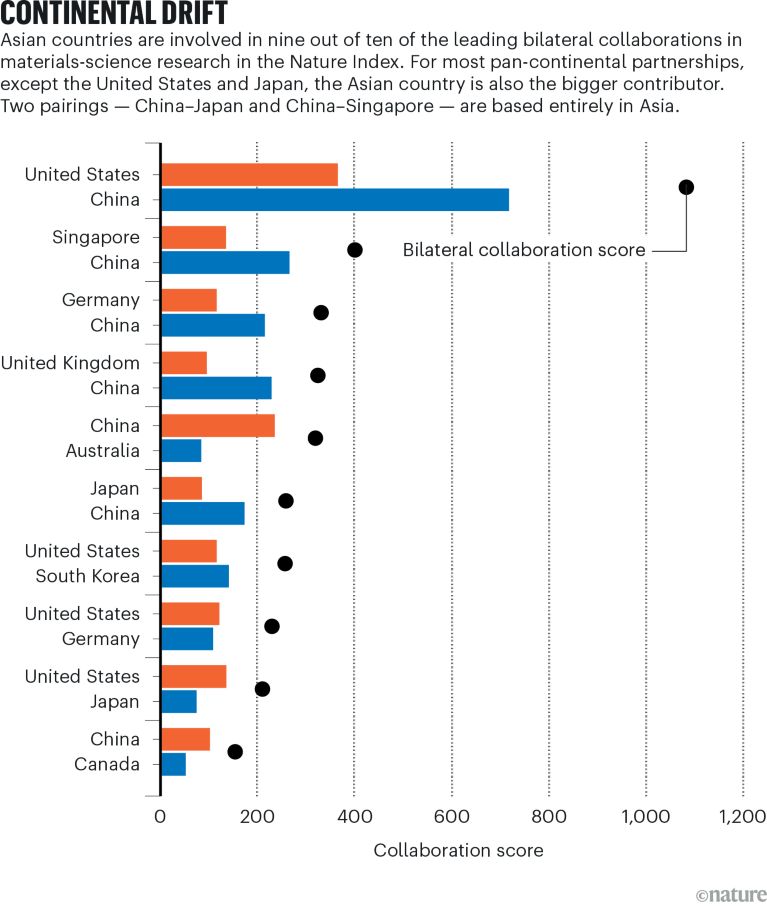

Source: Nature Index

In 2010, Domen was granted 10 years of funding to pursue his strategically significant research, an unprecedented length of grant for Japan. He says this made a huge difference compared with the usual five-year projects “because we could form long-term collaborations, including with industry, to make important progress”. At the project start, the team had initially planned a 1 m2 solar green hydrogen demonstration system, but in 2021, Domen and his industrial partners demonstrated a 100 m2 array of photocatalytic water-splitting reactors for green hydrogen production4.

Planning is under way for a next-generation system, using a higher performance catalyst, that will be demonstrated on a 3,000 m2 array. Now in its second phase, the project is increasingly funded by industry collaborations.

Photocatalytic materials research in Japan has been transformed over the course of his career, Domen notes. “When I was a graduate, there were only four photocatalysis research groups in Japan,” he says. “Now there are about 20, collaborating but also competing.”

The number of researchers in Asia’s well-funded green materials sector has become a major driver of scientific productivity, Ma agrees. “As the field has emerged as a hot research topic, many people have been drawn in, which brings opportunities for collaboration but also brings competitiveness,” he says. “You have to work harder — it’s a driving force.”

Green materials research is increasingly competitive across the region’s international borders, a result of the commercial potential it offers. Materials-science collaboration between Japan and China continues to grow, for instance, and is the second most-productive partnership in the region.

There is an acute awareness that economic goals often underpin cross-border relationships and might impact them as emerging technologies mature from fundamental research into serious commercial prospects. Japan’s government, for example, is wary of China’s potential to dominate emerging green industry markets, Domen says. “China is our very good collaborator and our very good competitor.”

But even if powerful economic drivers are helping to spur green technology development in Asia, this race to develop new products is still likely to help tackle climate change, bringing environmental benefits across the world.