Nuclear-energy deals by technology giants Amazon, Microsoft and Google have sparked media attention around the world in the past few months. But several companies, including Meta and Google, are also investing in another source of low-carbon energy — next-generation geothermal. The agreements show that this technology is “on the cusp” of widespread commercial success, says Lauren Boyd, a geologist who heads the Geothermal Technologies Office at the US Department of Energy (DoE) in Washington, DC.

Will AI’s huge energy demands spur a nuclear renaissance?

On 17 October, Fervo Energy, a start-up based in Houston, Texas, got a major boost as the US government gave the green light to the expansion of a geothermal plant Fervo is building in Beaver County, Utah. The project could eventually generate as much as 2,000 megawatts — a capacity comparable with that of two large nuclear reactors. Although getting to that point could take a while, the plant already has 400 MW of capacity in the pipeline, and will be ready to provide around-the-clock power to Google’s energy-hungry data centres, and other customers, by 2028. In August, another start-up, Sage Geosystems, announced a partnership with Facebook’s parent company Meta to deliver up to 150 MW of geothermal power to Meta’s data centres by 2027.

Not your grandma’s geothermal

Sage, Fervo and other companies worldwide are racing to tap the heat that’s constantly flowing from Earth’s depths. Unlike conventional geothermal energy, which has been around for the better part of a century, these projects do not rely on natural hot springs; instead, they create their own.

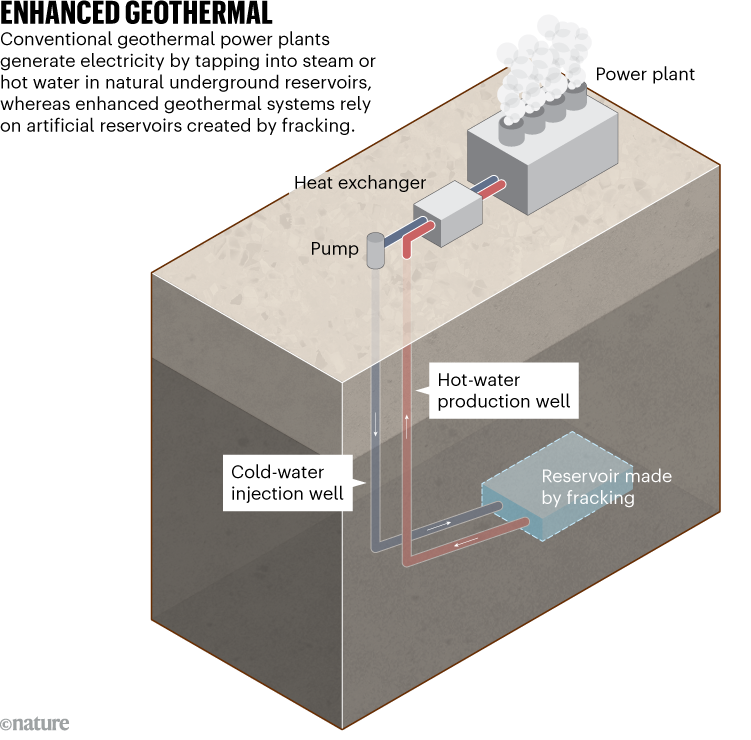

The process involves drilling a borehole up to several kilometres deep, where the rocks are at a temperature of around 200 °C, and injecting water and sand at high pressure. This makes fractures in the rocks, increasing their permeability and creating a reservoir of heated water that can be continuously extracted through a second borehole. The hot, pressurized water is then used to generate electricity (see ‘Enhanced geothermal’).

This approach — known as enhanced geothermal systems (EGS) — has been attempted since the 1970s, but most projects have failed to extract notable amounts of energy.

Improvements in the past decade have come from adopting techniques that are used in the oil and gas industry, including better ways to fracture the rock and drill horizontally. Researchers have had to adapt those methods to drilling in rock at high temperatures, or find their own solutions. Boyd was directly involved in Utah FORGE, a DoE project to push EGS technology, which she says has introduced a number of innovations that have nearly halved the drilling costs.

Tunnelling sideways

Horizontal drilling, in particular, has been crucial for the success of EGS, says Joseph Moore, a geologist at the University of Utah in Salt Lake City, because the cracks made by fracking “tend to go vertically”. A horizontal borehole will cross many fractures and inject water into — or extract it from — a large volume of rock, says Moore, who heads Utah FORGE.

South Korea’s most-destructive quake probably triggered by geothermal plant

Although Utah FORGE has pushed the boundaries of EGS, and has developed techniques to drill into deeper and hotter rock than had previously been possible, Fervo’s nearby Utah plant and two earlier pilot projects have shown that the EGS concept can work using off-the-shelf tools, says Fervo’s senior geologist, Emma McConville, who is based in Reno, Nevada, “We can deliver massive amounts of geothermal to the market at extremely fast rates,” she says.

Executives at next-generation geothermal companies say that the vast workforce of people who are experienced in drilling for oil and gas is a readily available resource that should help their businesses to grow quickly. There is also a substantial overlap with the oil and gas industry in terms of equipment: the 30-metre-tall derricks for drilling wells are the same ones that would otherwise be used for extracting hydrocarbons, says McConville. “Being able to keep those going — but working for carbon-free energy — is one of my favourite parts of this industry.”

Reducing quake risks

The development of EGS has been held up partly because the hydraulic fracturing (fracking) processes involved can cause seismic activity. Some projects, including one in Basel, Switzerland, and another in Pohang, South Korea, have had to shut down because the fracking was linked to considerable earthquake activity.

Utah FORGE, Fervo and other companies are following DoE guidelines to limit induced seismicity, and they continuously monitor their sites with seismographs. “If we exceed a certain threshold, we shut down,” says McConville. Although the fracking does produce quakes, these have typically been of a magnitude less than 2, she adds. “If we’re careful and we’re not drilling into faults that could slip, we shouldn’t get events that you can feel,” says Moore.

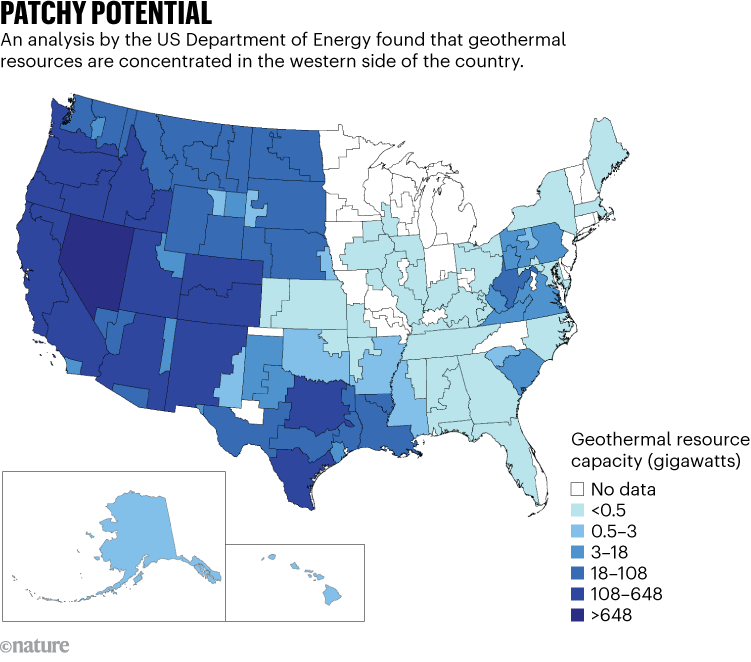

Source: Enhanced Geothermal Shot Analysis for the Geothermal Technologies Office.

Another company has taken an even more risk-averse approach. Eavor, based in Calgary, Canada, calls its geothermal technology ‘advanced’ rather than ‘enhanced’, and foregoes fracking altogether. Instead, the company has developed a sophisticated magnetic guidance system, in which the drill heads from the two boreholes guide each other and form closed loops underground. “There’s no GPS when you are four and a half kilometres underground,” says Matt Toews, the company’s chief technology officer.

In an Eavor project, each borehole branches out into a grid of parallel, horizontal pipes, which then reconnect at the other borehole. This also means that the water never comes into direct contact with the rock, but has to absorb heat through the pipes’ casings. “The advantage is that we don’t have to frack,” says Carsten Reinhold, chief geologist at Eavor’s German arm in Düsseldorf.

Eavor is building its first commercial geothermal plant near Geretsried, Germany, and this should start exploiting 160 °C water from a depth of 4,500 m next year. The plant will mostly provide heating to buildings in the nearby town, but will also generate about 8 MW of electricity.

Future markets

Drilling to kilometres of depth is a very expensive business, and each borehole can cost millions to make. Although costs are expected to come down, next-generation geothermal is still projected to be more expensive than many other forms of energy. But because it can be available at any time, it could complement low-carbon resources that are inherently variable, such as solar and wind. “It fills a niche where there are really not many options,” says energy-systems researcher Wilson Ricks at Princeton University in New Jersey. Its main competitors would then be other expensive energy sources, such as nuclear, biomass and hydrogen.

How the hydrogen revolution can help save the planet — and how it can’t

Whether or not geothermal will be an economical solution will also depend, in large part, on geography. In general, the deeper you drill, the hotter the rock, but the vagaries of geology mean that the depths at which rocks reach temperatures high enough to enable electricity generation — around 200 °C — vary greatly around the world. High temperatures tend to be found closest to the surface in regions with active volcanism, or where the continental crust is thinner than average. A survey by the DoE, for example, shows that the western side of the United States has a much greater potential than the eastern side for extracting this energy at a profit (see ‘Patchy potential’).

In a study published early this year in Nature Energy1, Ricks and collaborators, including Fervo co-founder Jack Norbeck, simulated US energy markets. Ricks says they found that geothermal could be cheaper than nuclear in much of the western United States. But a crucial assumption in the study was that plants can ramp their electricity generation up and down in response to swings in demand. Whether this can be done without causing excessive wear-and-tear will be a major test for upcoming facilities.